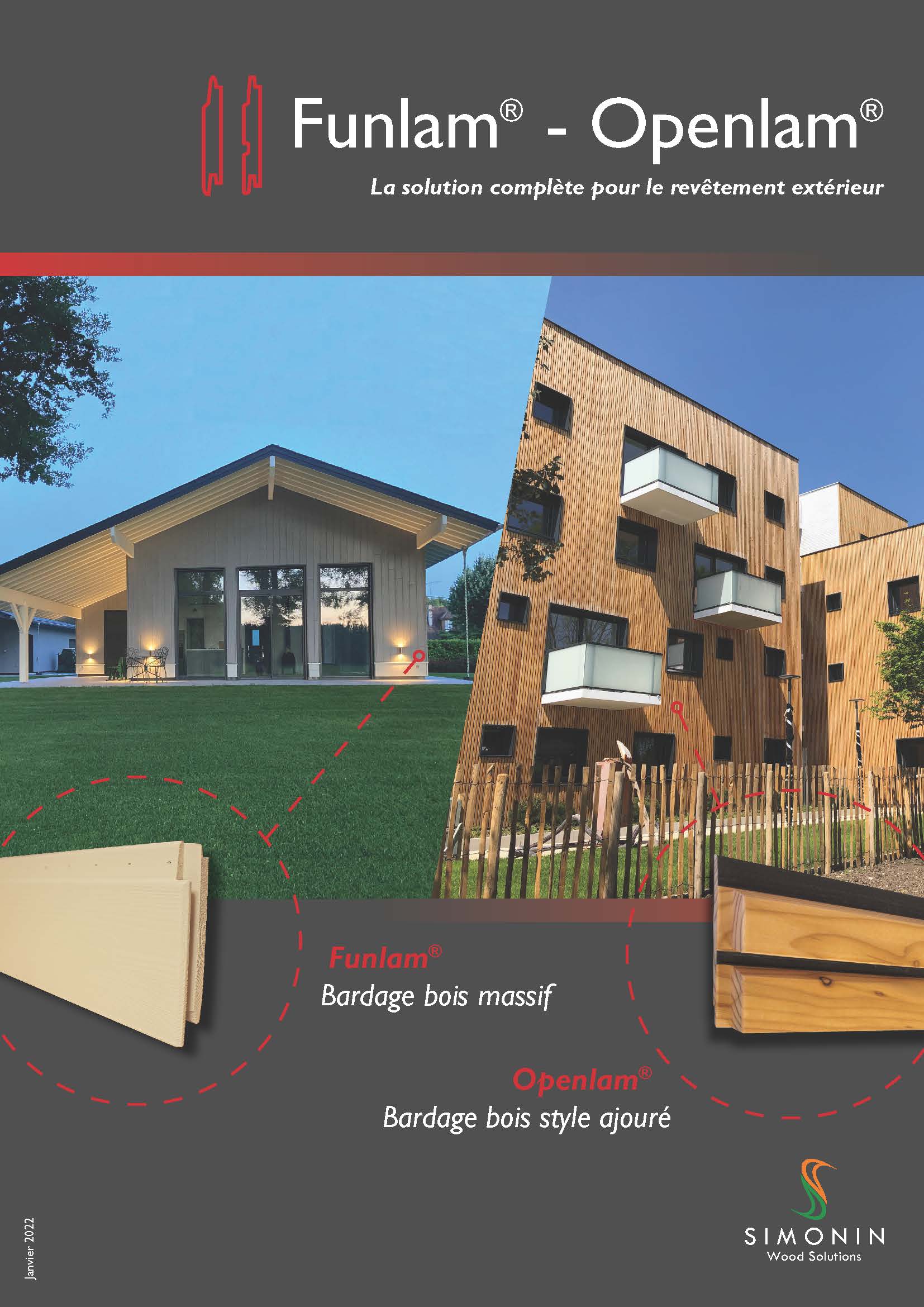

Openlam: The wood openwork cladding

The complete solution for the external cladding

Thanks to 25 years of experience in manufacturing wood components, we offer for your construction or renovation project, the complete solution for the external cladding: solid timber cladding, timber open work style cladding and window and door casings

In order to ensure better sustainability of the outer shell, we have designed and developed an exclusive line of window and door casings for your home. These solve all air & water sealing problems as well as enhancing your home’s exterior.

Trimmed for longevity, our cladding Openlam® and our casings give your home a stylish, air & water resistant outer skin in all extreme weather conditions.

The quality of SIMONIN timber cladding

In order to supply an aesthetic and reliable product, one of its kind, our team pays tremendous attention to each and every detail of our external cladding. Our wooden cladding will perfectly match your timber construction, whether timber framed house or wooden extension.

Supply of high-quality timber

All the wood used for the manufacture of our cladding comes from sustainably managed and managed forests in accordance with current standards.

Spruce

Our woods are selected from colder regions, where they are slower grown and have a fine grain. All the natural defects are removed during manufacturing. To ensure a beautiful visual appeal, our cladding will only contain small sound knots; the natural variation of the grain of our timber resembles flames highlighting the natural characteristics of the timber. We choose naturally resistant softwood, Spruce. Spruce takes paint particularly well. The Spruce is brushed to emphasise the grain and then three layers of acrylic paint is applied to increase the longevity of the cladding.

Larch

Our selection process of arch is identical to the above, we choose high-quality wood. For this, larch exclusively comes from Switzerland or Austria. Using the same manufacturing process as the spruce siding , the larch is purged of all defects and sapwood. Naturally resistant (class 3), it can be installed without any treatment and without any finishing.

Various styles of installation: vertical, horizontal, inclined

Wood selection – finger jointing

- sorting and purging of irregularities

- no waste: 100% usable

- optimum stability and durability

Brushing (on Openlam®)

- supersedes the natural erosion

- improved paint adherence

Invisible fastening

- pre-drilling of every board

- precision nail setting

- no risk of splitting

- fast and easy workability

Factory milled end cuts

High-End finish

- class 3 anti-termite treatment

- stained or painted

- mechanical processing

The easily installed cladding

The careful and selective sorting of the timber ensures straightness and easy fitting of each board. Time saving in the implementation is significant and loss is minimized.

For all types of construction and renovation

The Simonin range applies to all types of construction and renovation. The great flexibility of installation makes it possible to adapt to all architectural styles.

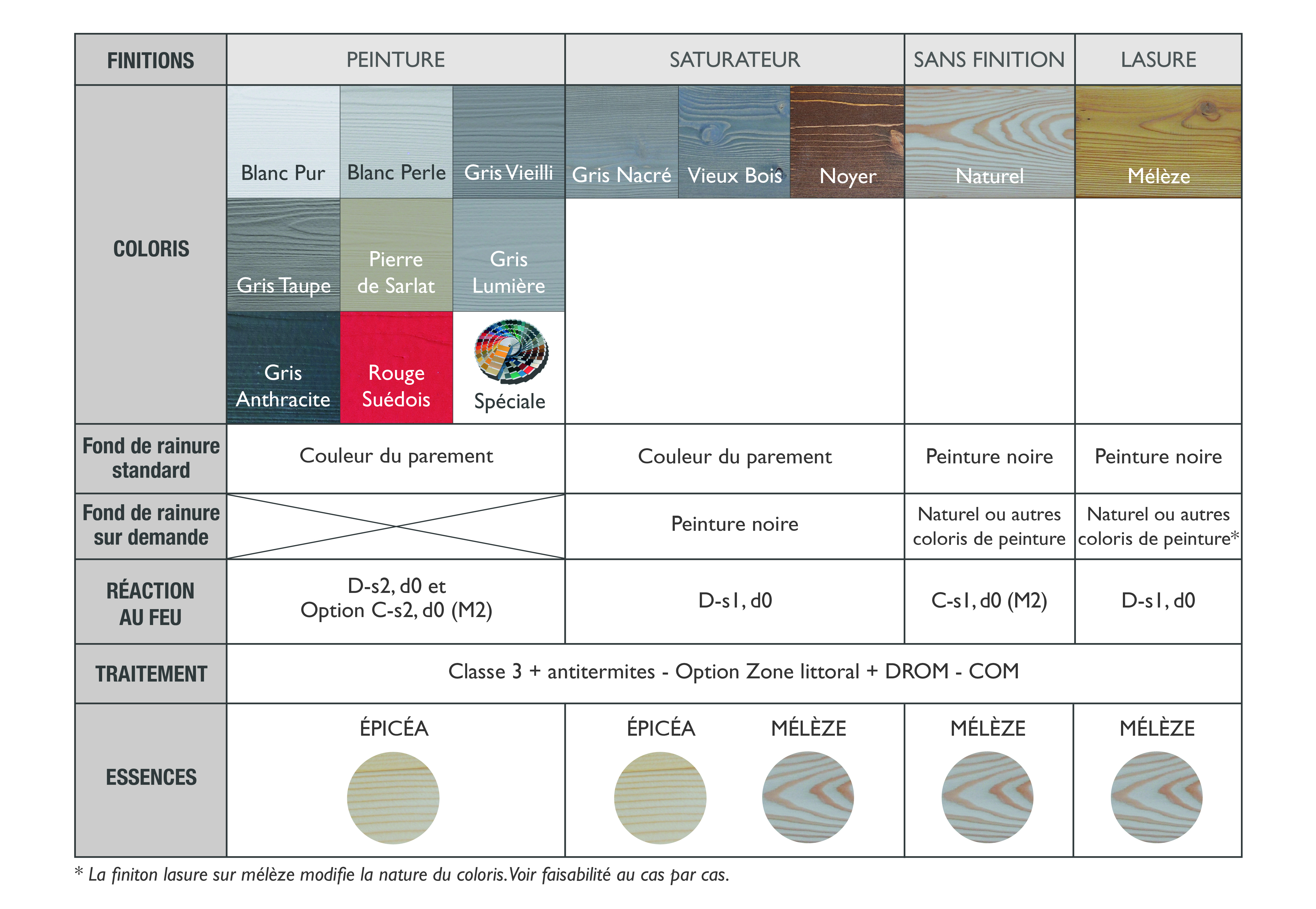

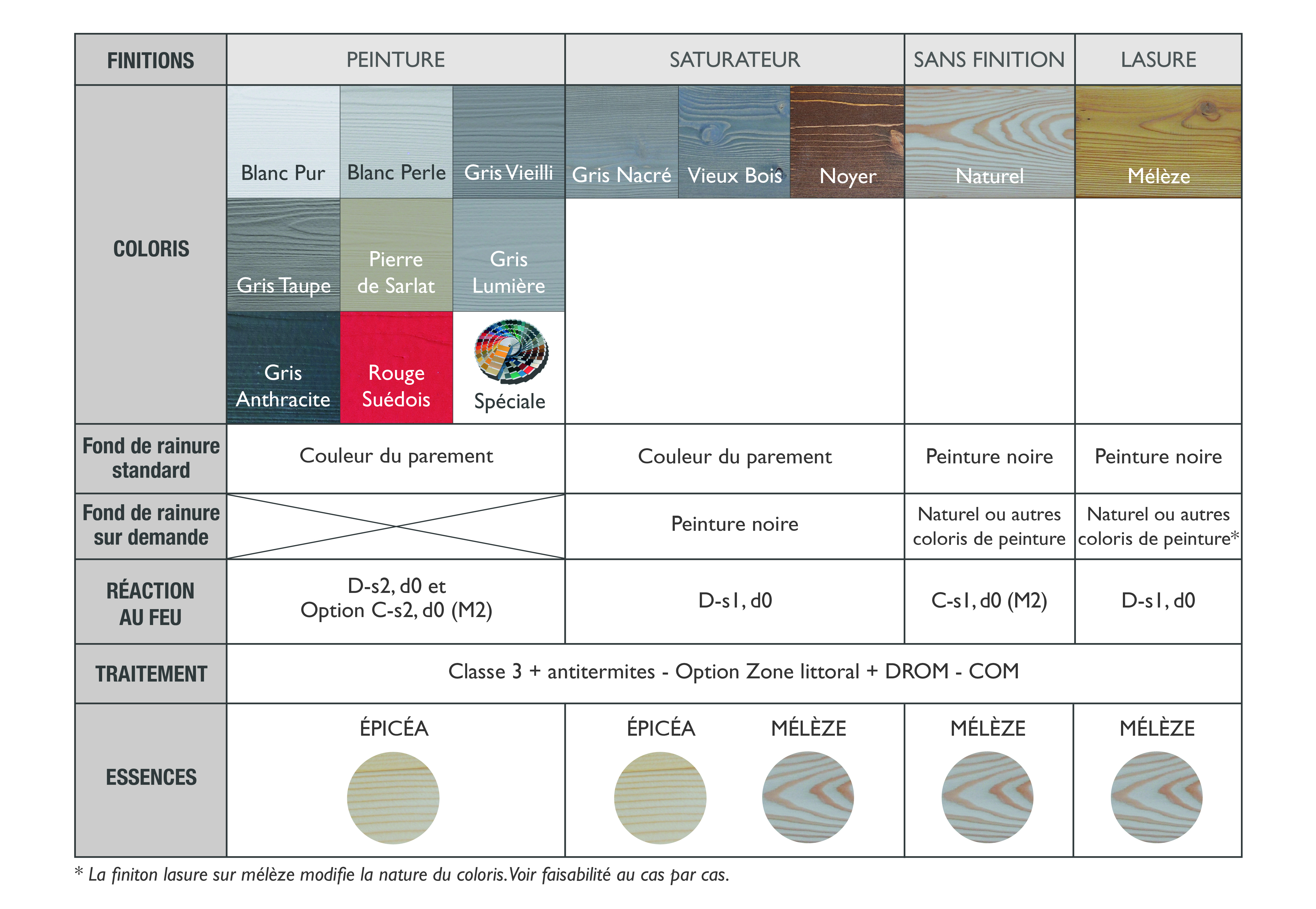

Paint finish

The paint we use has a satin appearance, it’s based on acrylic resin and is specifically designed for exterior wood. It has excellent adhesion while remaining flexible. The coating is highly resistant against abrasion and has water-repellent properties.

On the front the spruce Openlam® profiles get a layer of acrylic primer and two coats of acrylic paint with denibbing between each layer. A layer of acrylic primer is applied on the back.

The painting is done on an industrial scale with high performance technical means. This powerful technical equipment such as an automatic paint line and a drying tunnel guarantees a very regular application. This method applies 3 – 4 times more paint than a manual application and gives the product a much higher resistance.

We offer 8 standard shades in acrylic paint. According to quantities it is also possible to choose from a number of more than 1000 shades to paint your individual cladding.

Saturator finish

The water-based saturator we use is a product specially designed for the protection of exterior woods commonly used in joinery and cladding. It provides a non-film-forming protection on exterior cladding and joinery and gives your facades a uniform finish, with a pre-weathered look. This limits humidity exchange.

The saturator is a non film-forming product, this prevents the peeling of the protective layer.

Matt and resembling wood.

Gray timber cladding easy to maintain.

We offer 3 standard colours which are applicable to our spruce and larch cladding.

The rendering of the same color is different according to the essence of wood on which it is applied.

Larch stain finish (available only on larch)

The stain allows to keep the colour WOOD.

The 3 layer manufacturing process used for the paint is identic to the one of the stain

First a layer of UV protection, followed by two coats of acrylic stain with denibbing between each layer. The back receives a waterproof layer to ensure against-swing.

Two colours of stain are available for spruce and one for larch.

Slight differences in color may appear between samples of woodstain and different productions.

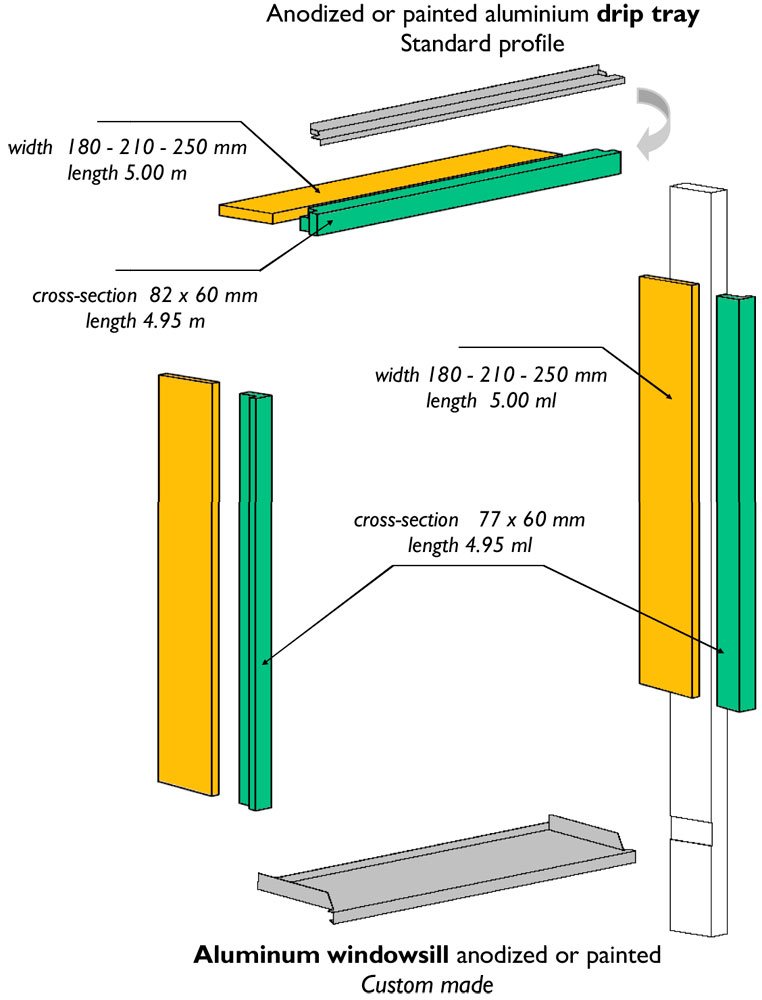

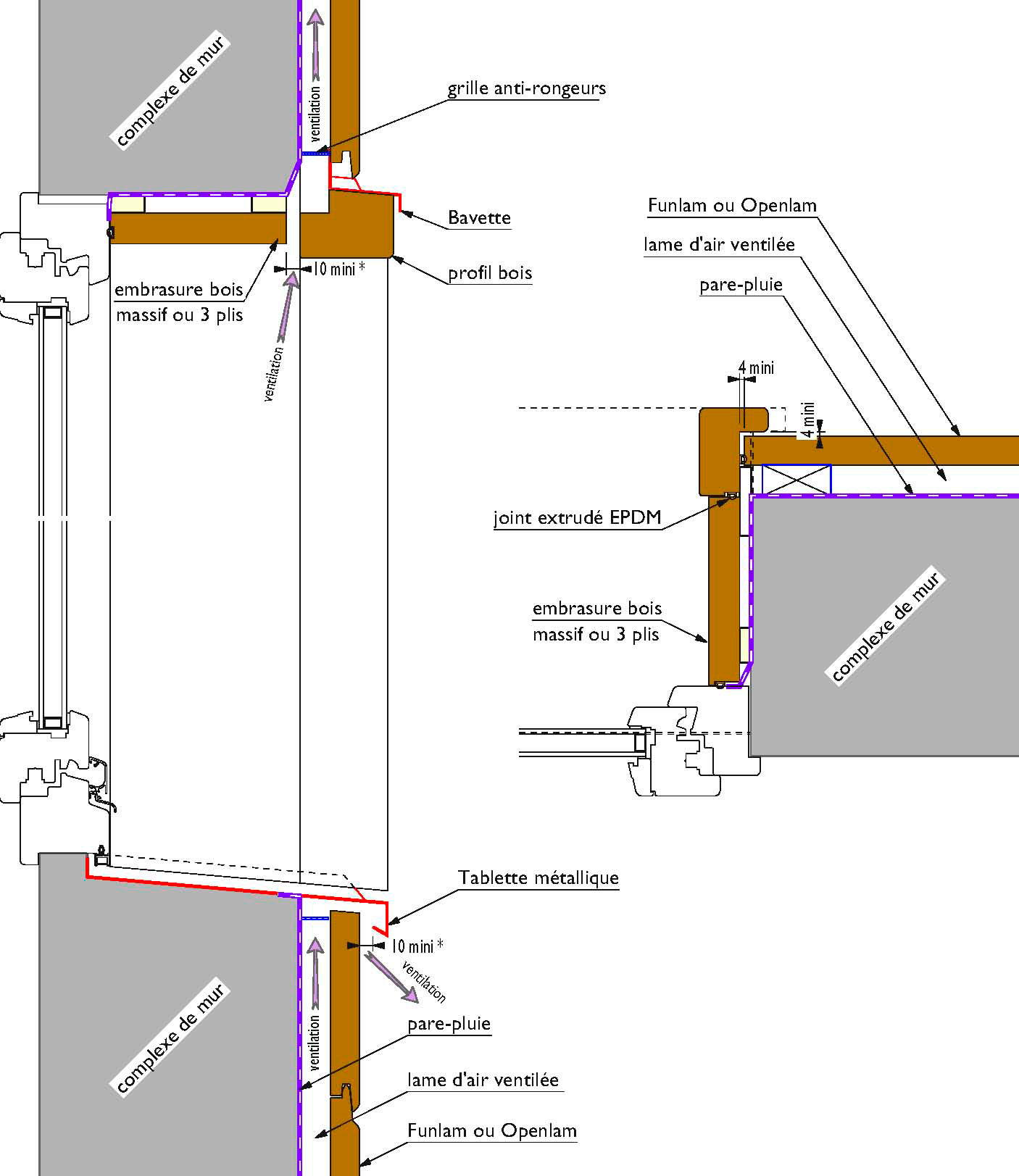

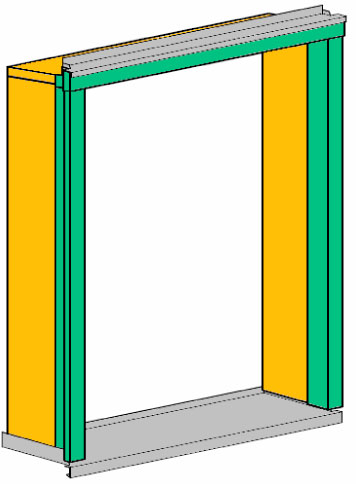

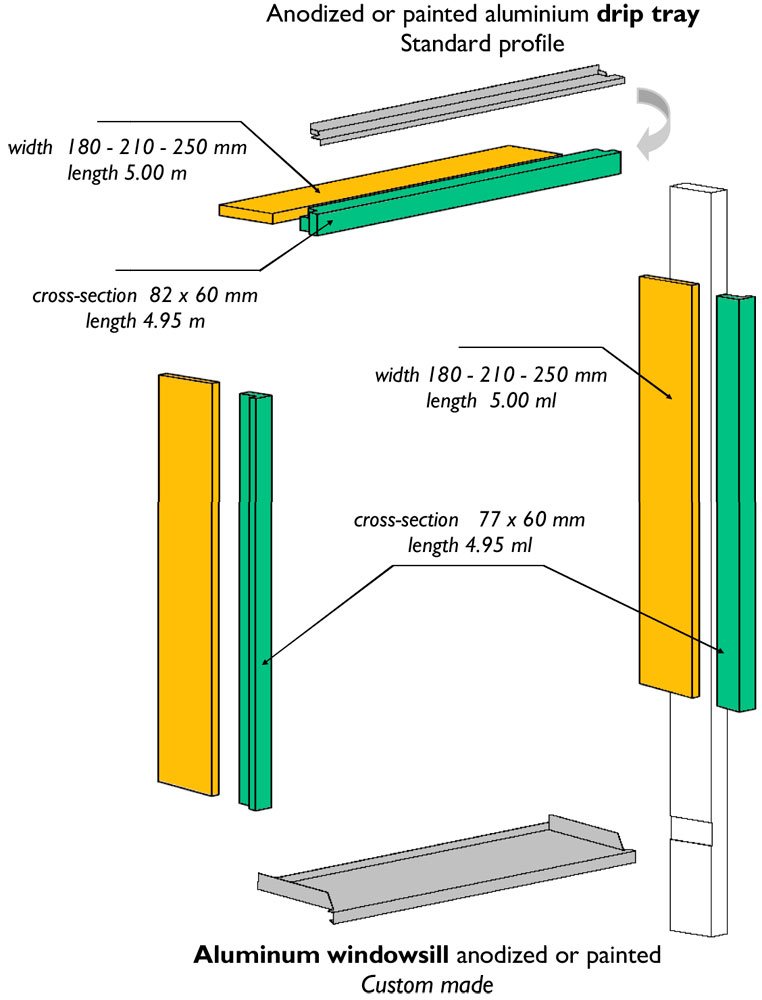

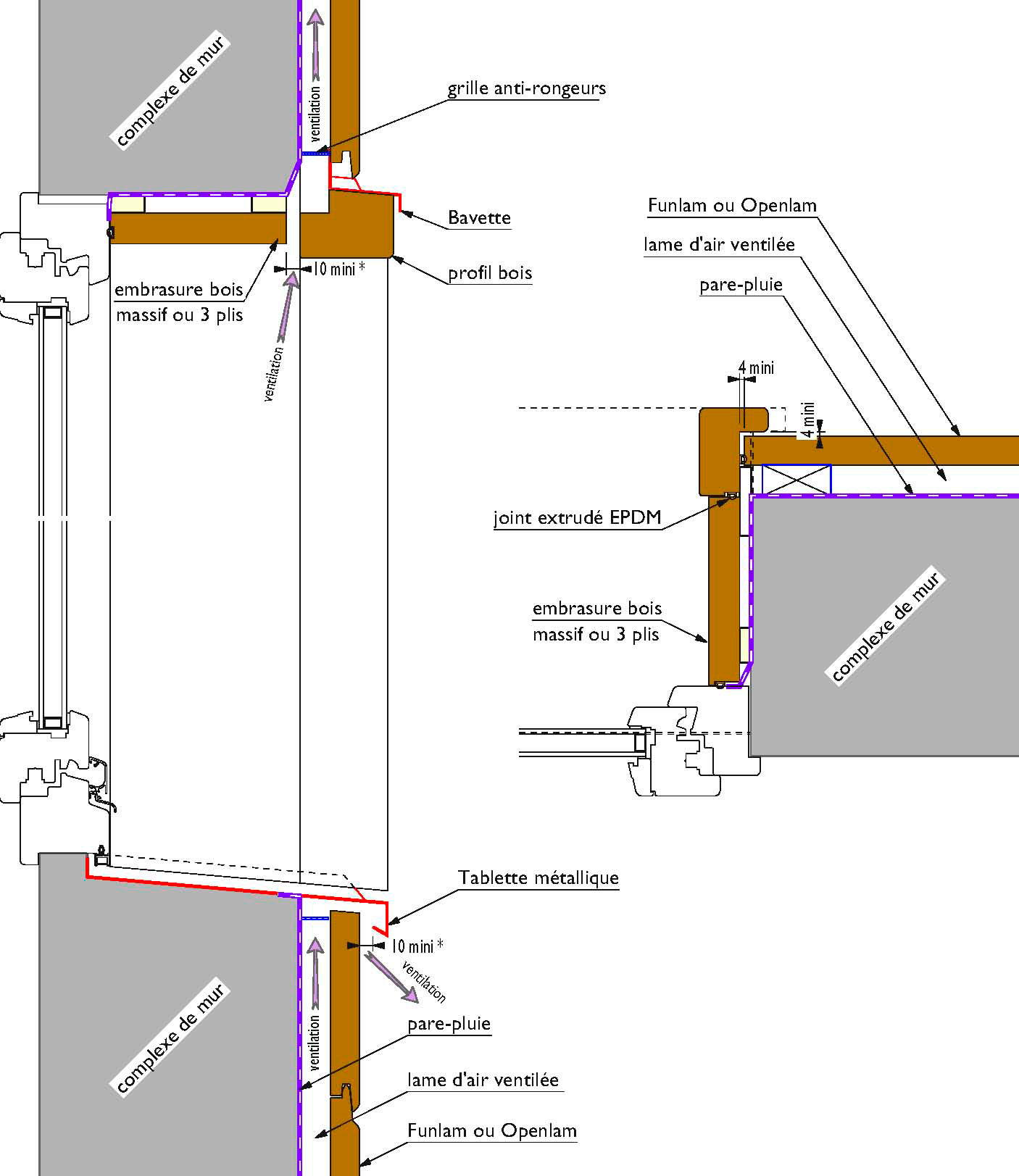

The complete solution for casings

In addition to our cladding, and to complete the siding of your home we offer exclusive joinery casings which perfectly finish windows and doors.

The full package

- Water and Airtight

- Modular with shutters or blinds

- Modular with joinery

- Solid in time

- Individual colours *

*available in painted spruce, larch or aluminium

Principle of wood framing

Casings also available in aluminium

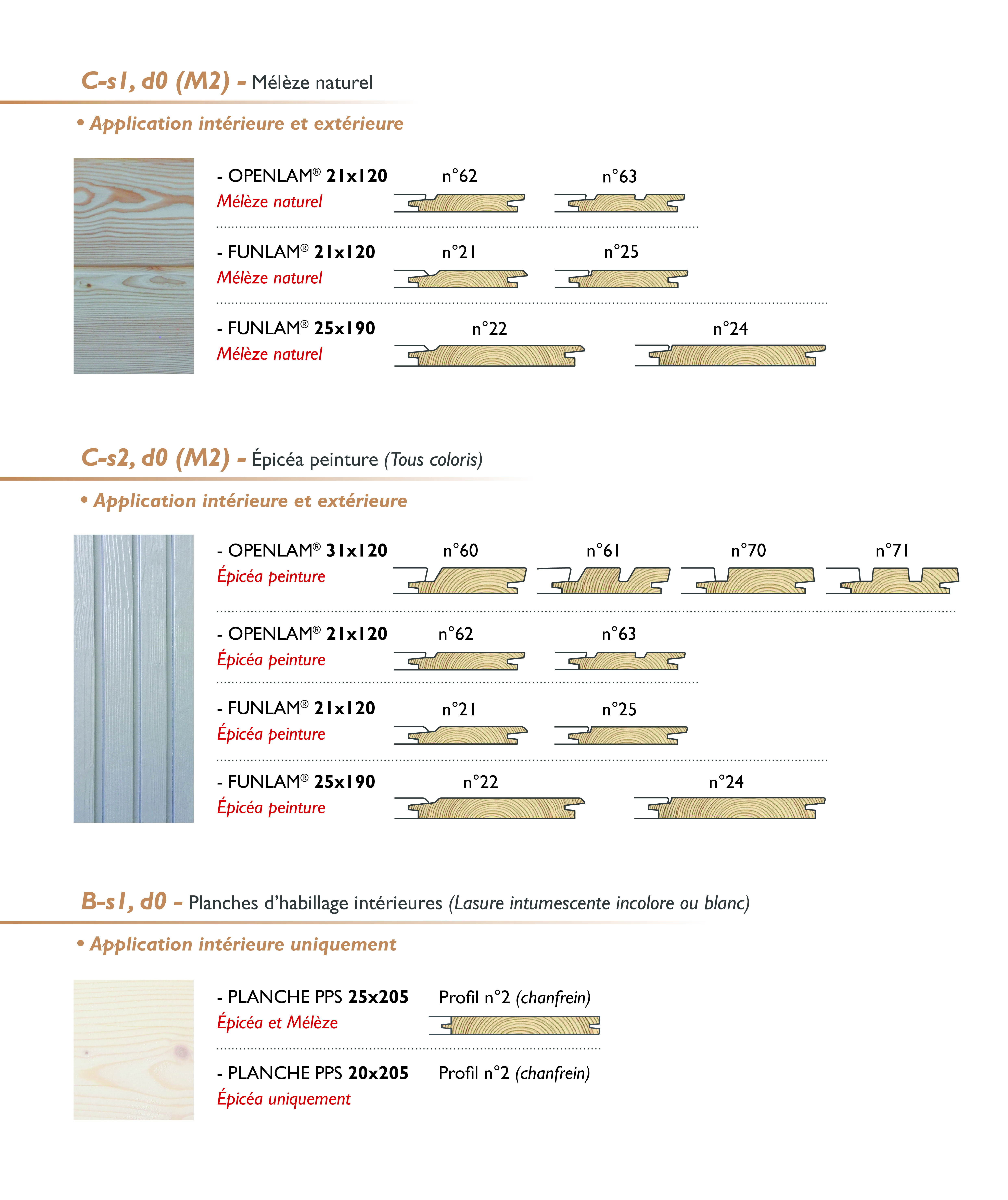

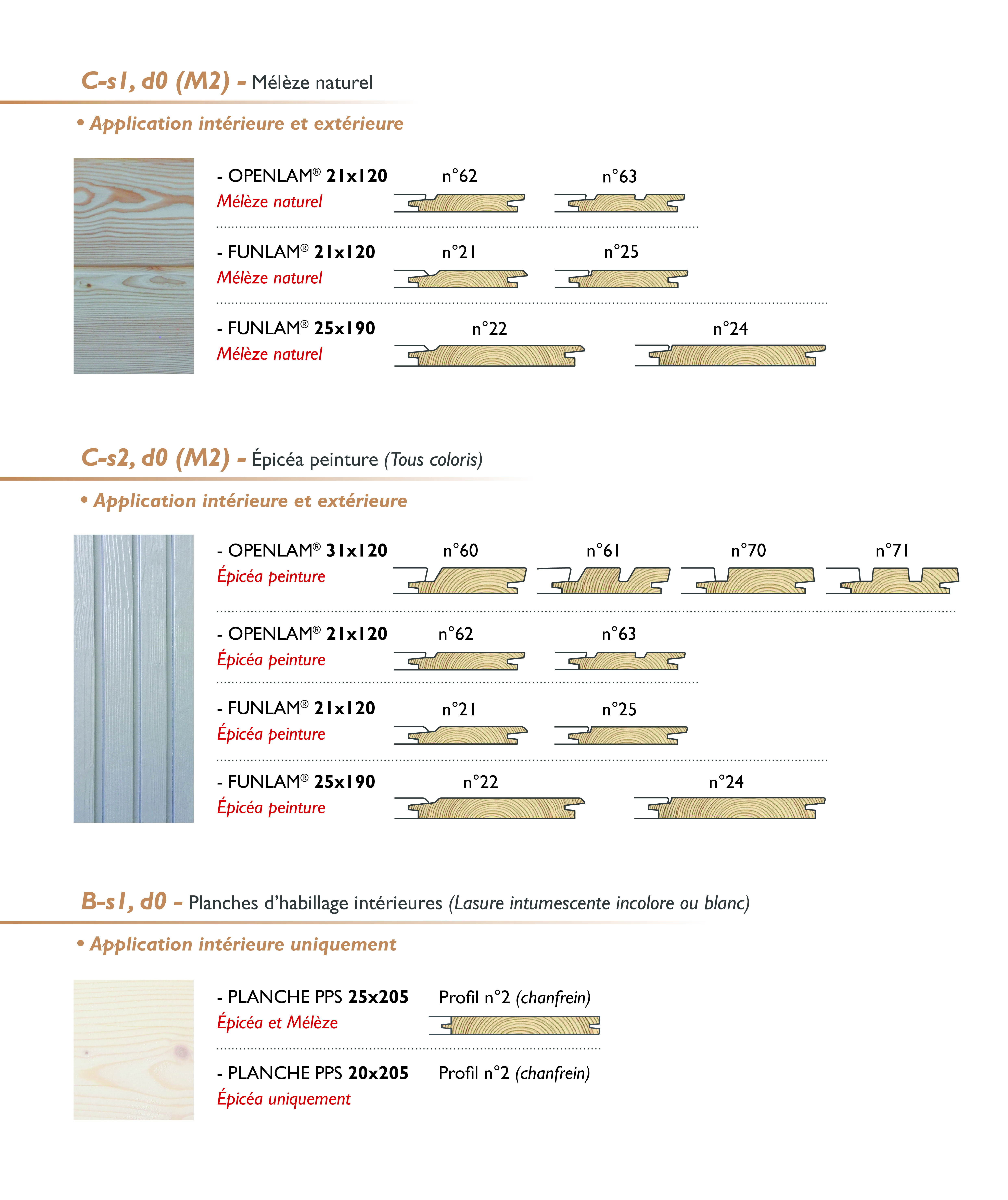

Fire regulations : the solution for your projects

The current fire regulations provide for many obligations in terms of exterior or interior cladding. Rank B or C is requested on many projects.

To meet these requirements we propose you :

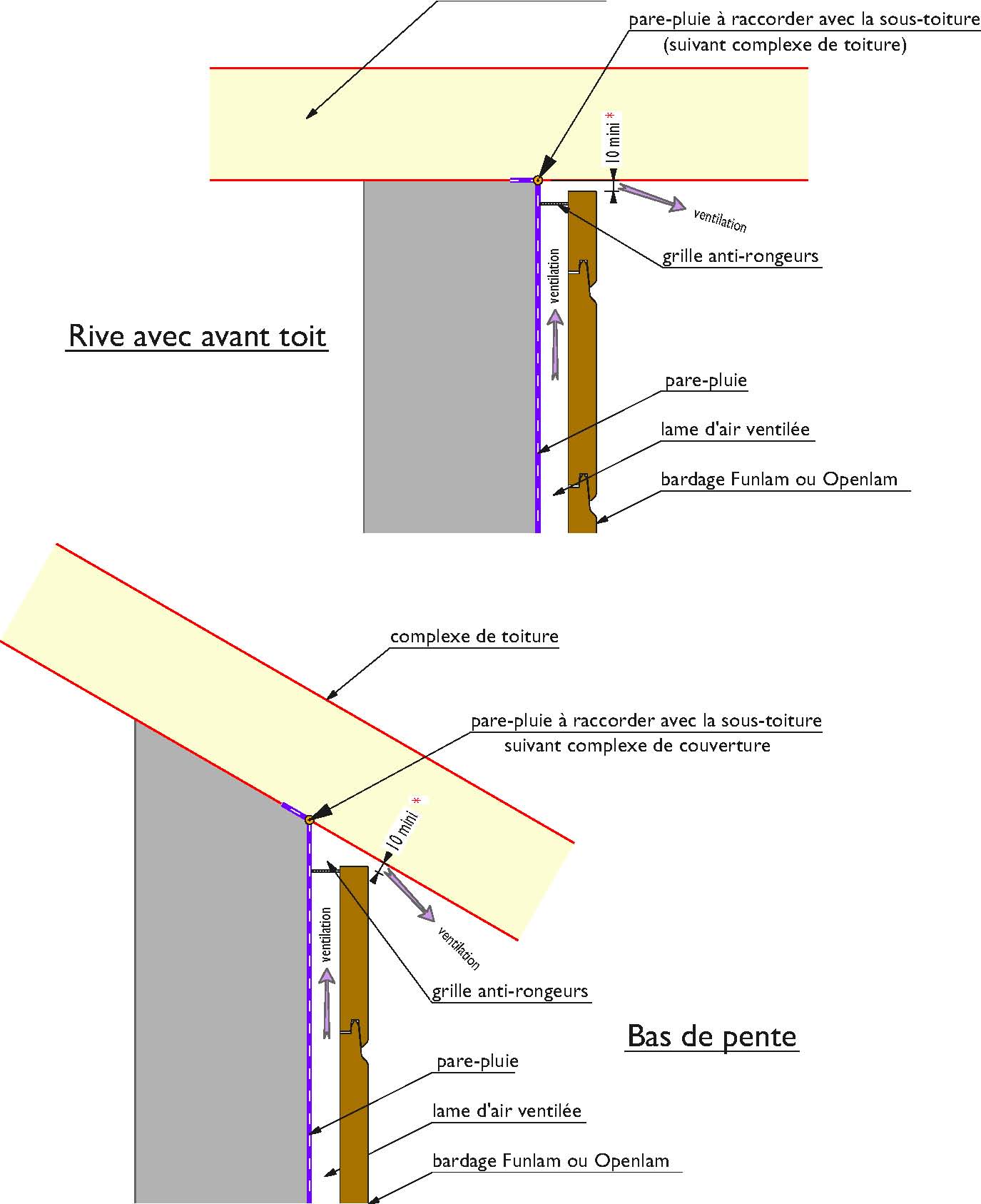

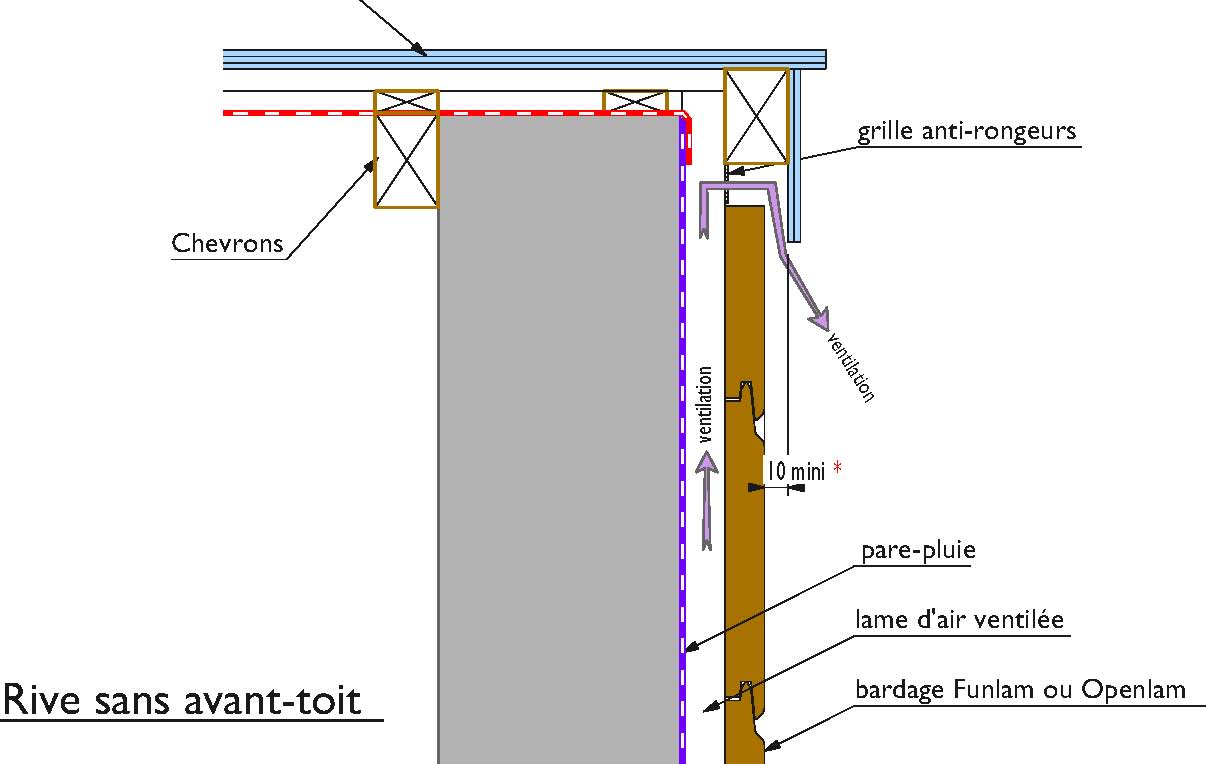

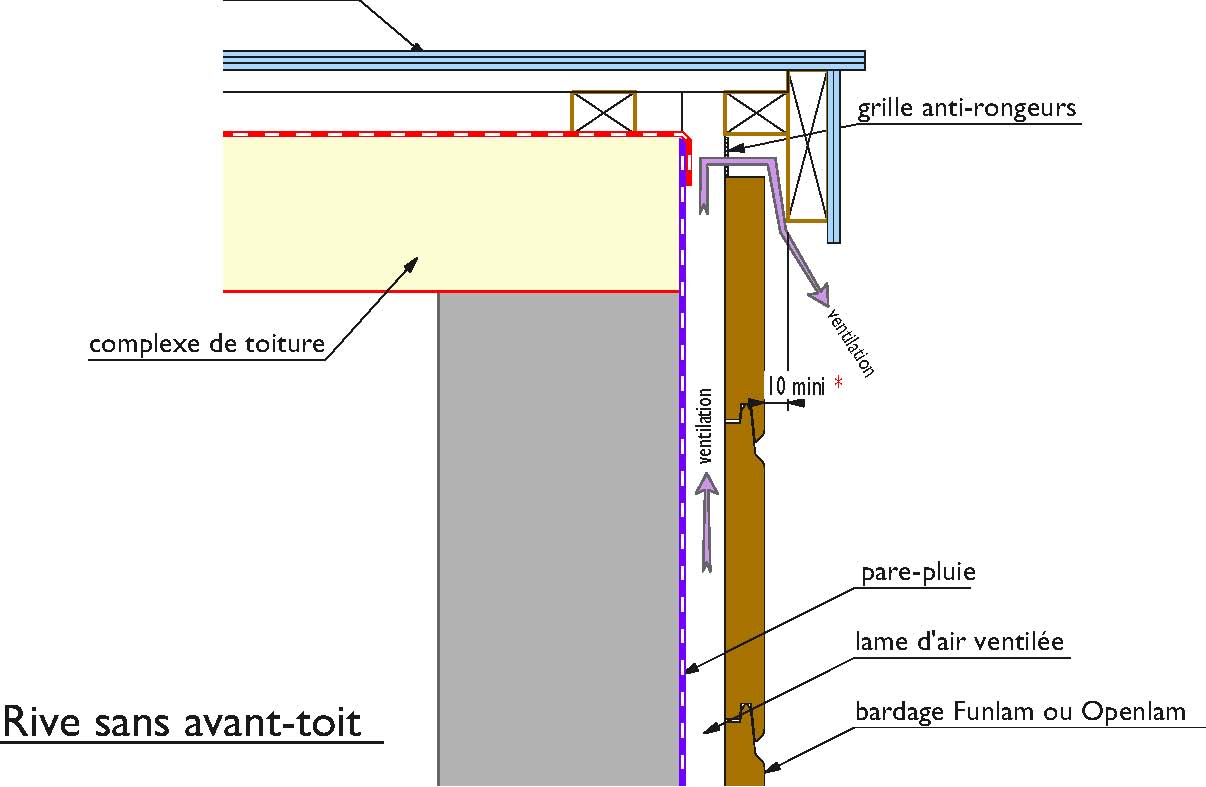

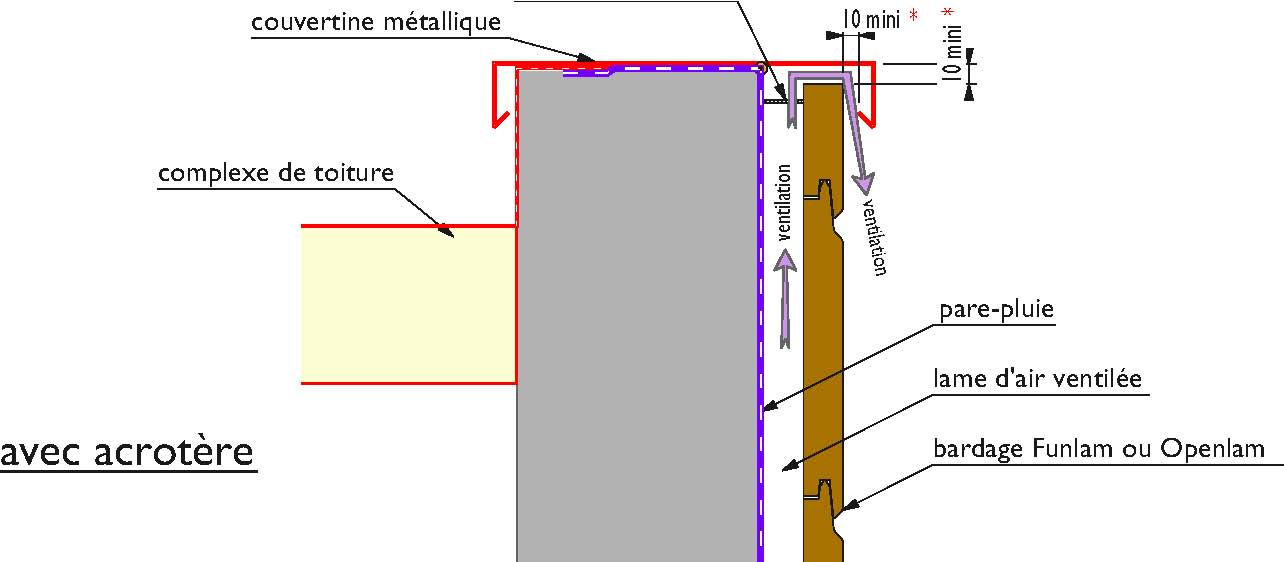

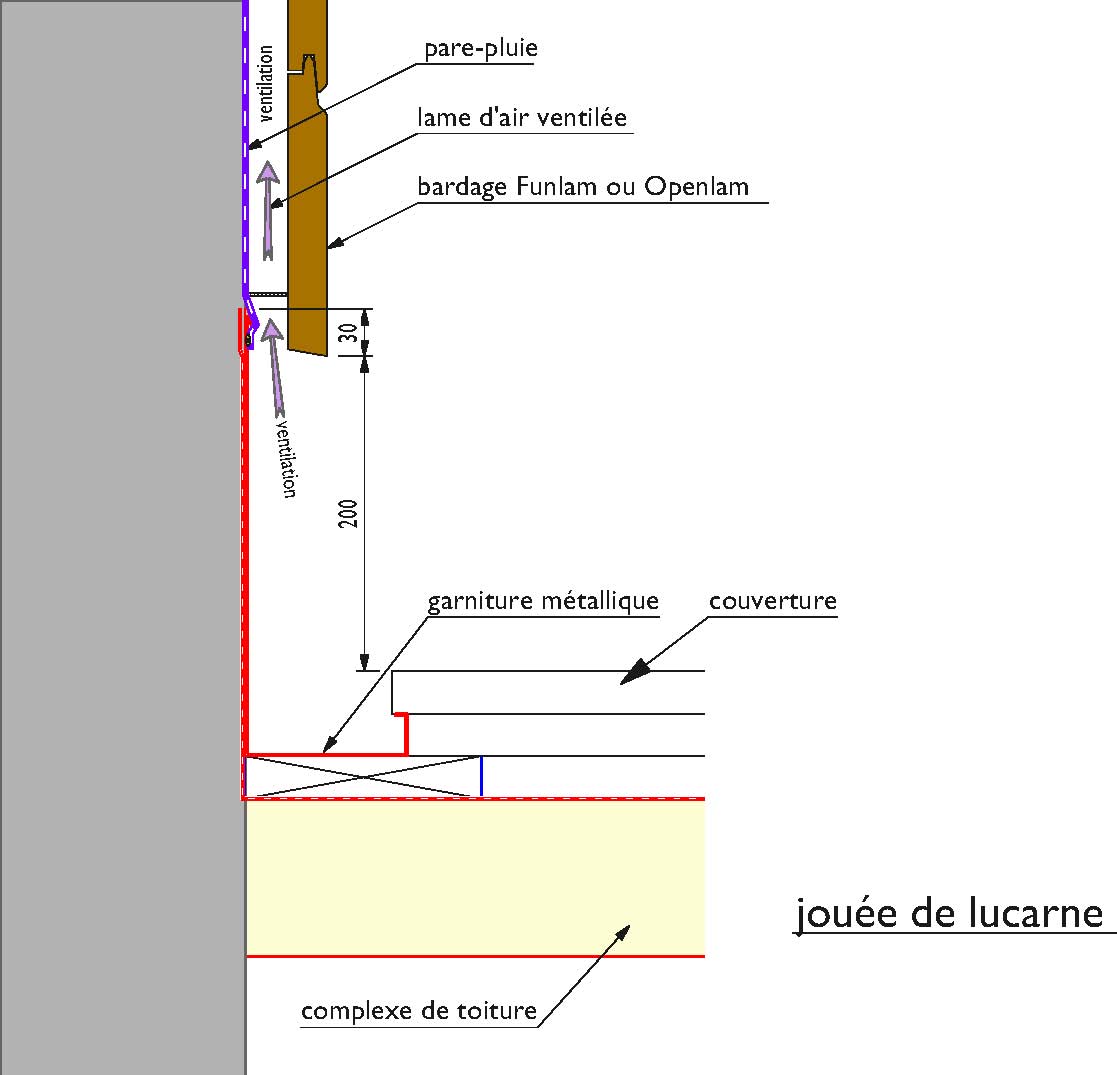

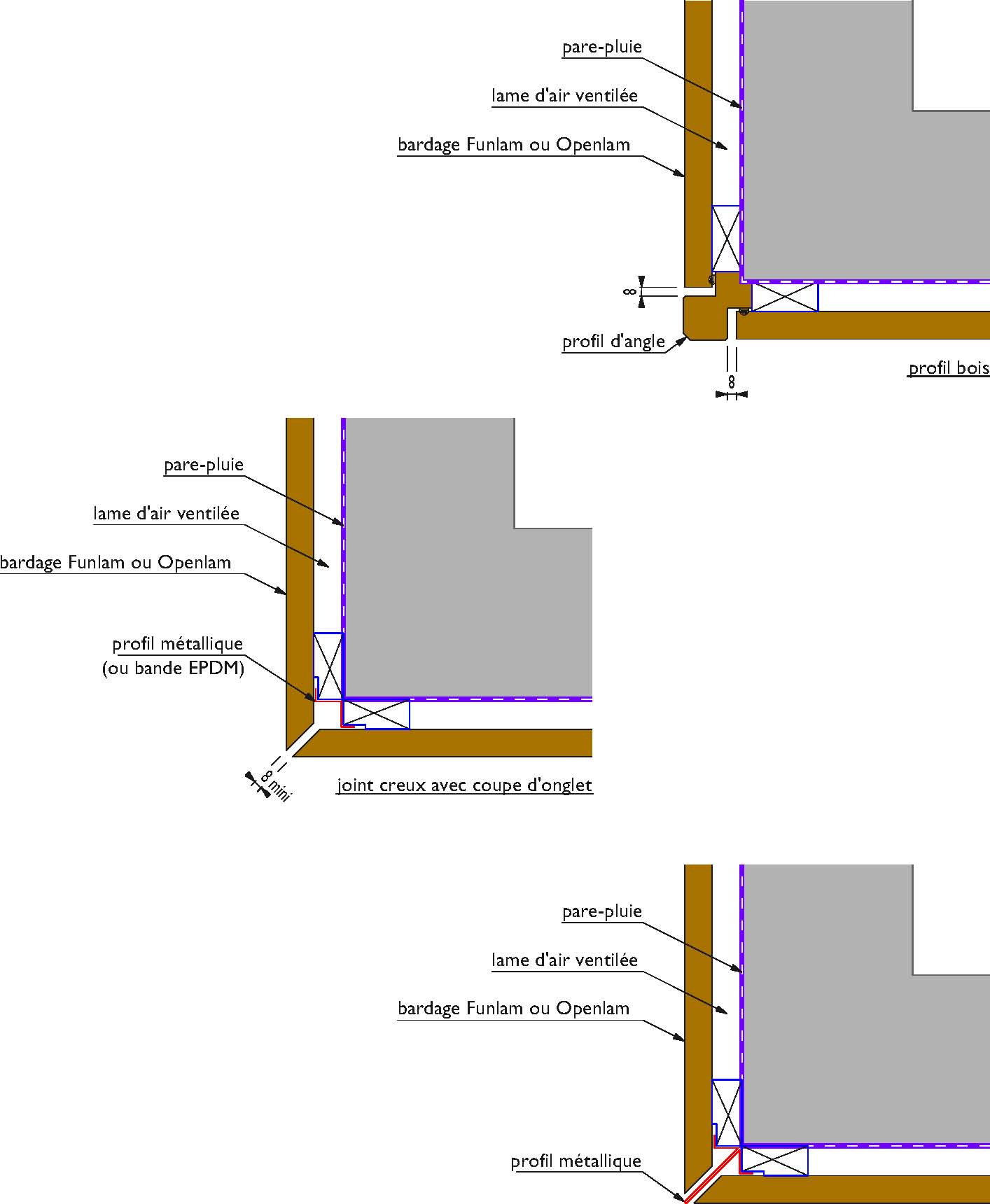

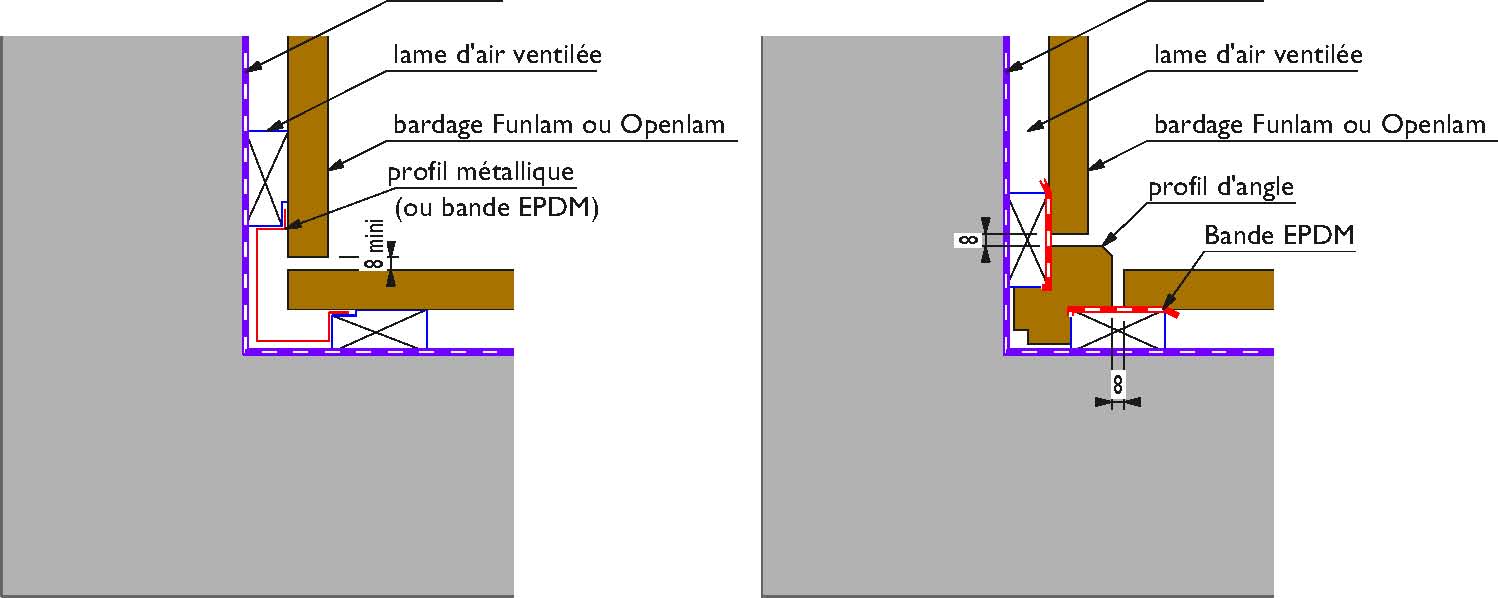

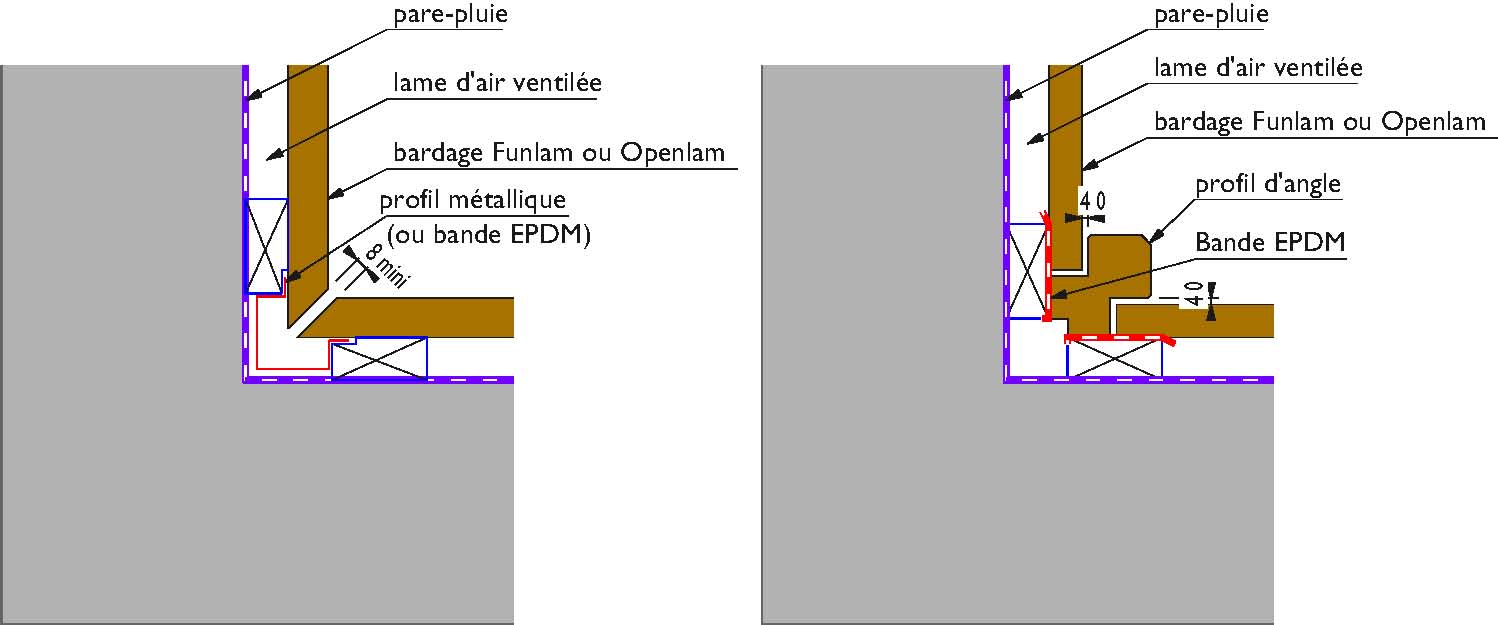

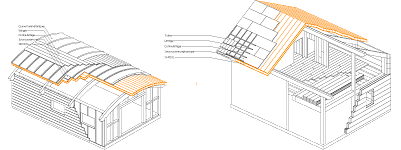

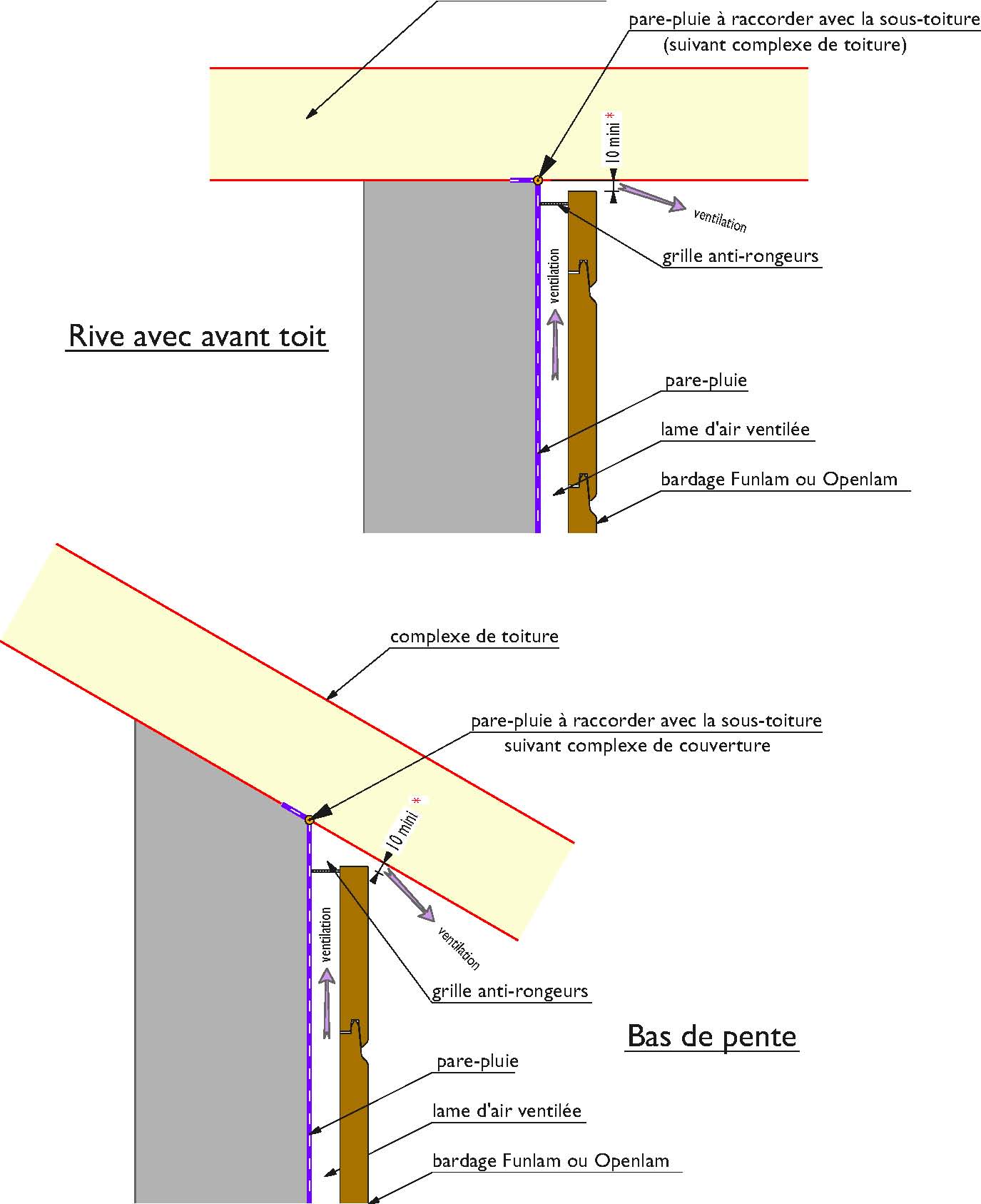

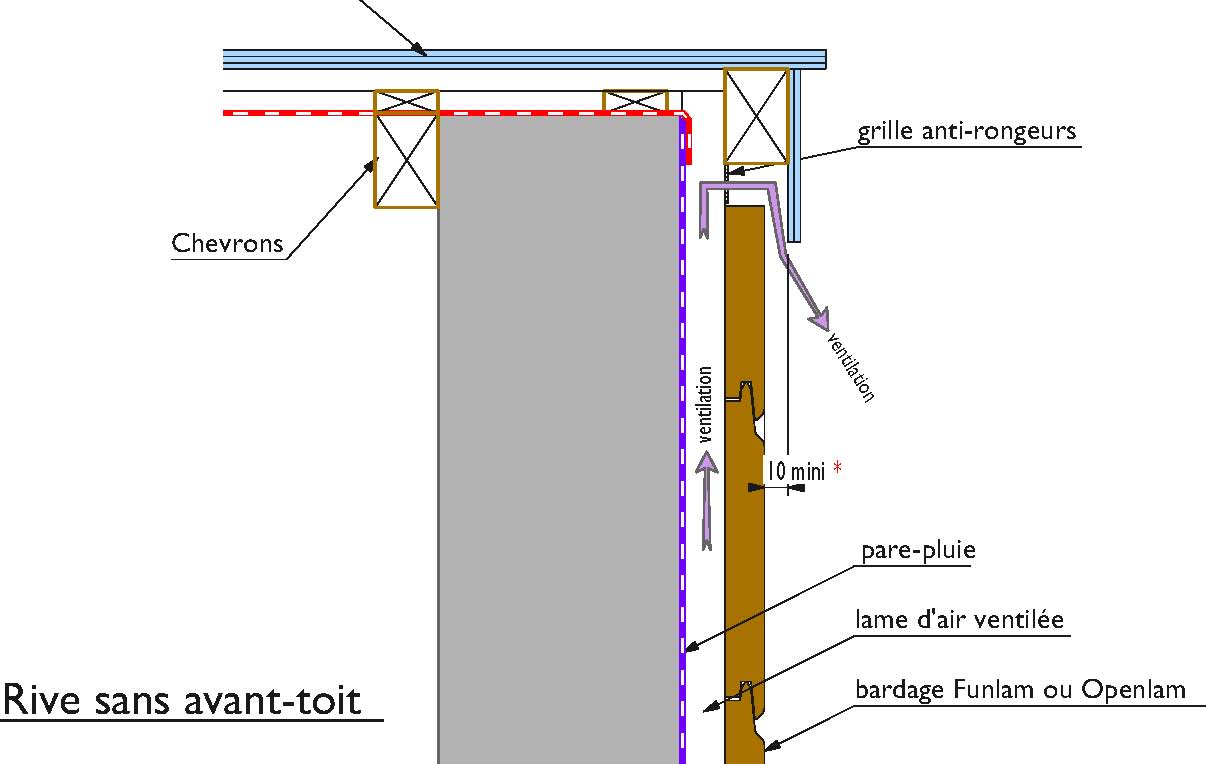

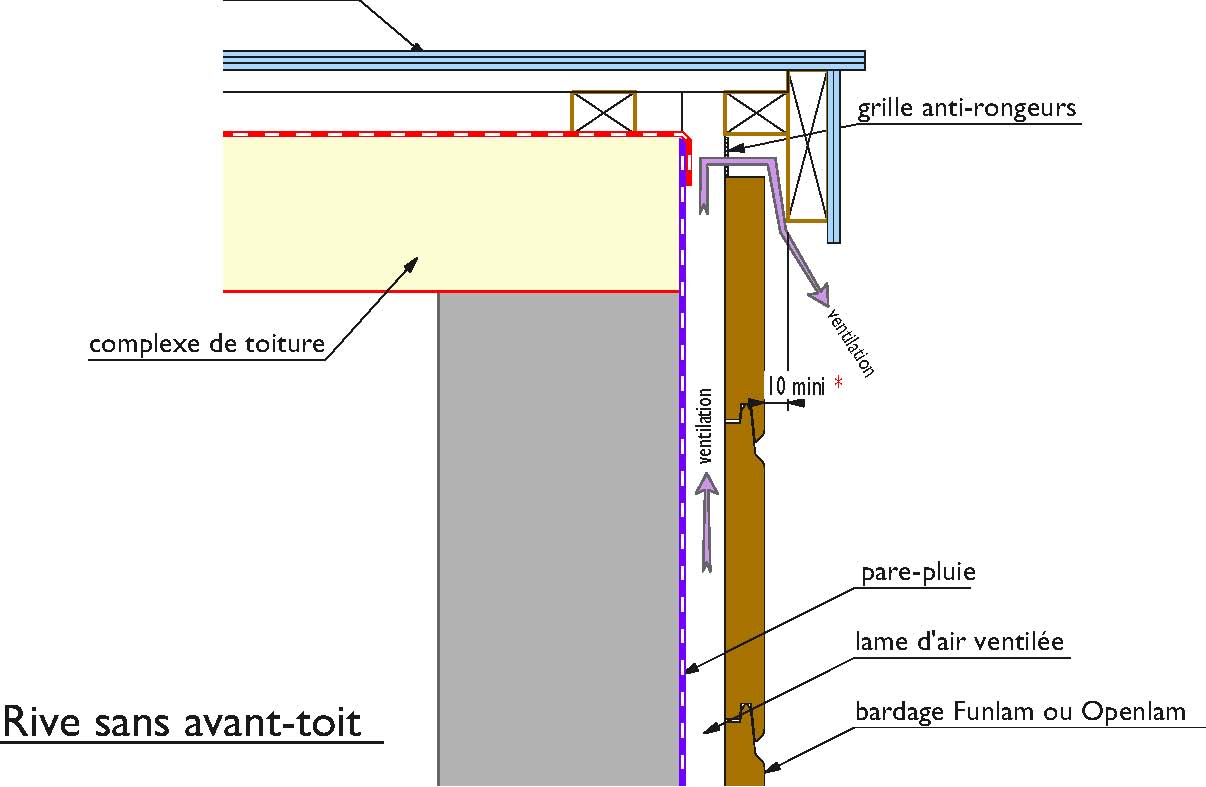

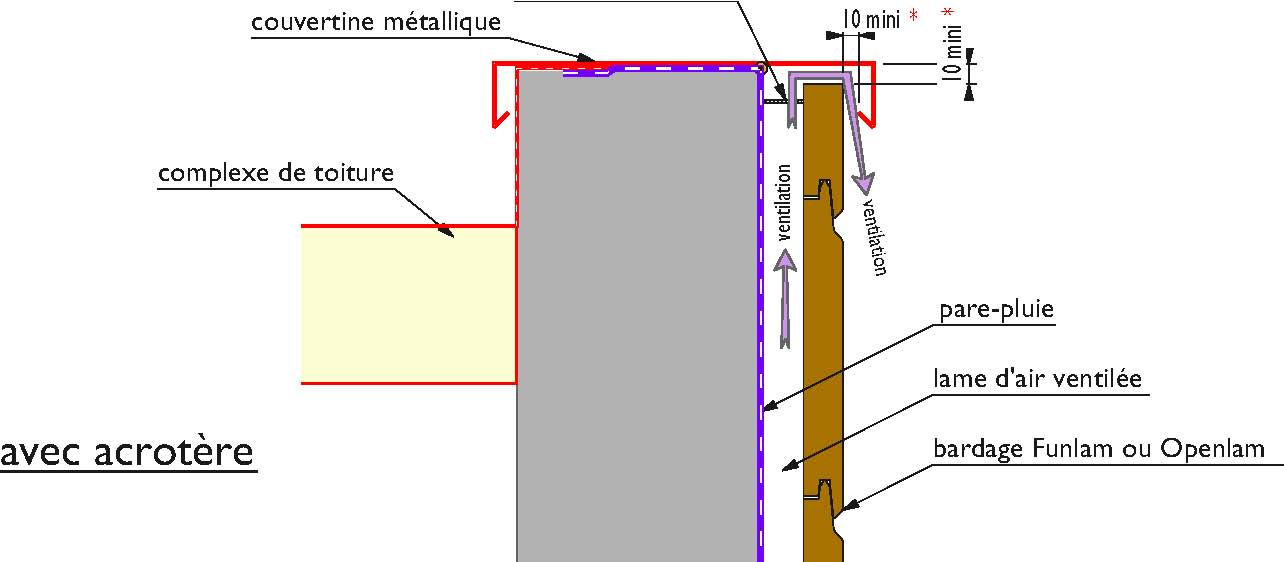

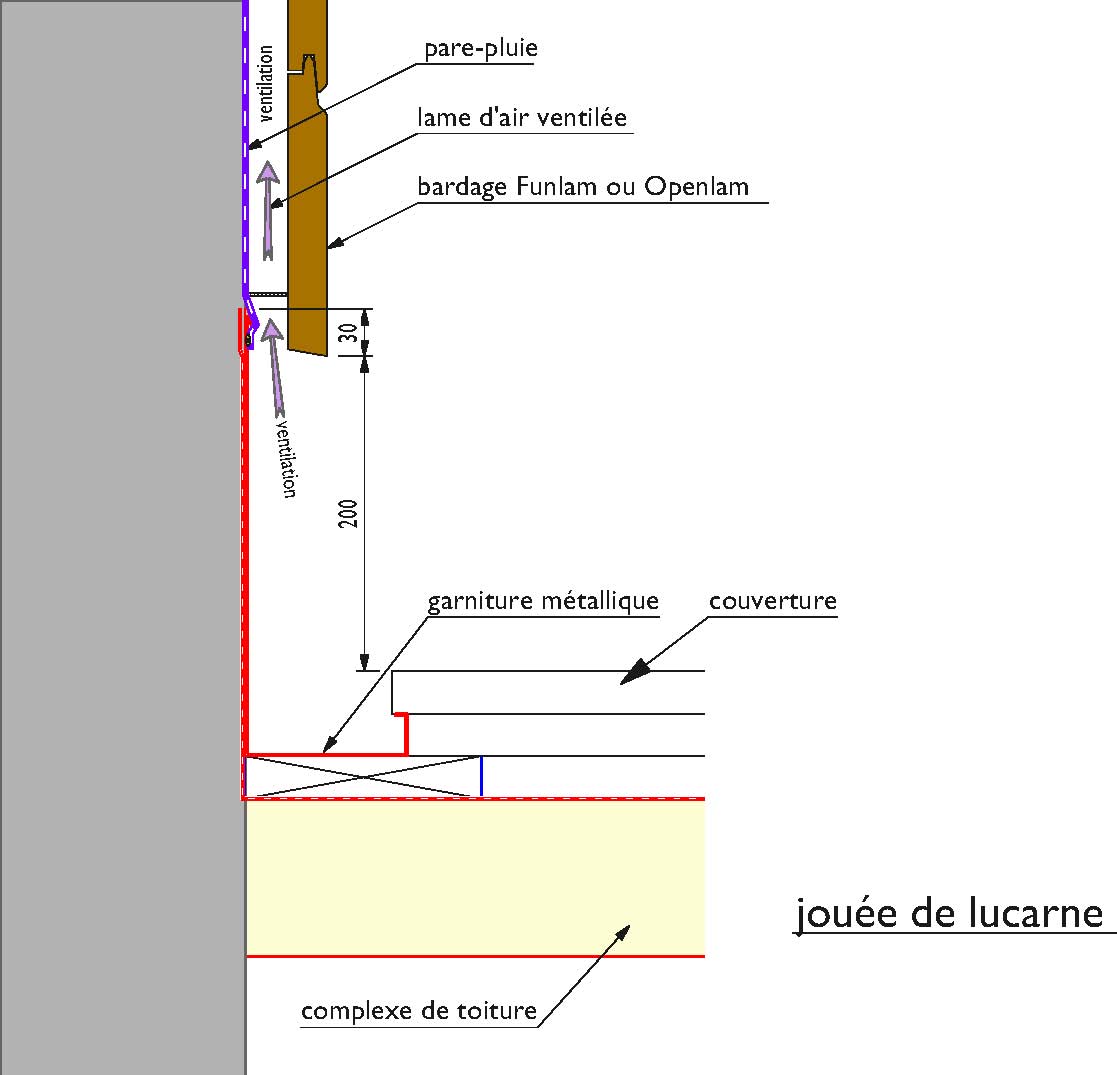

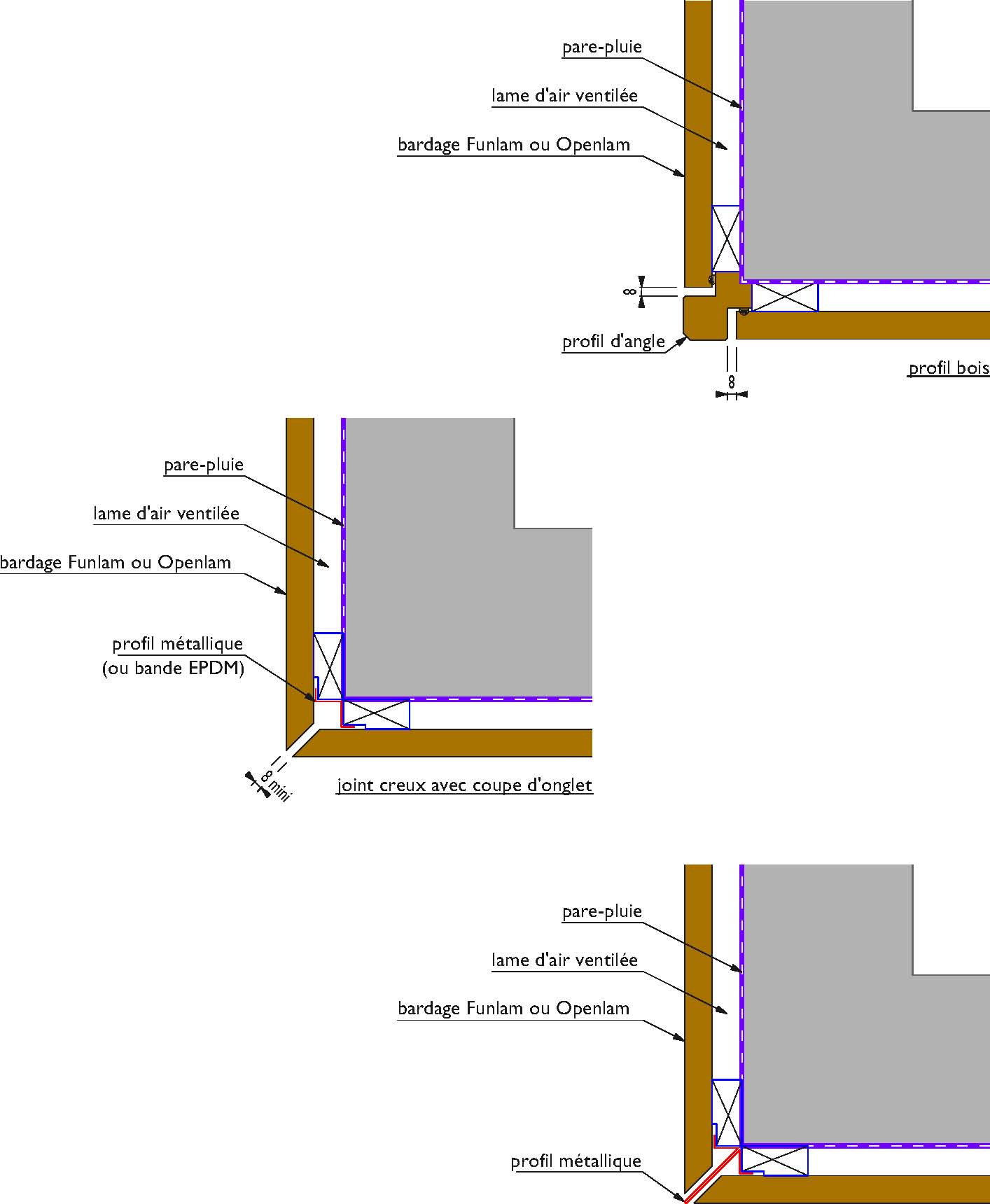

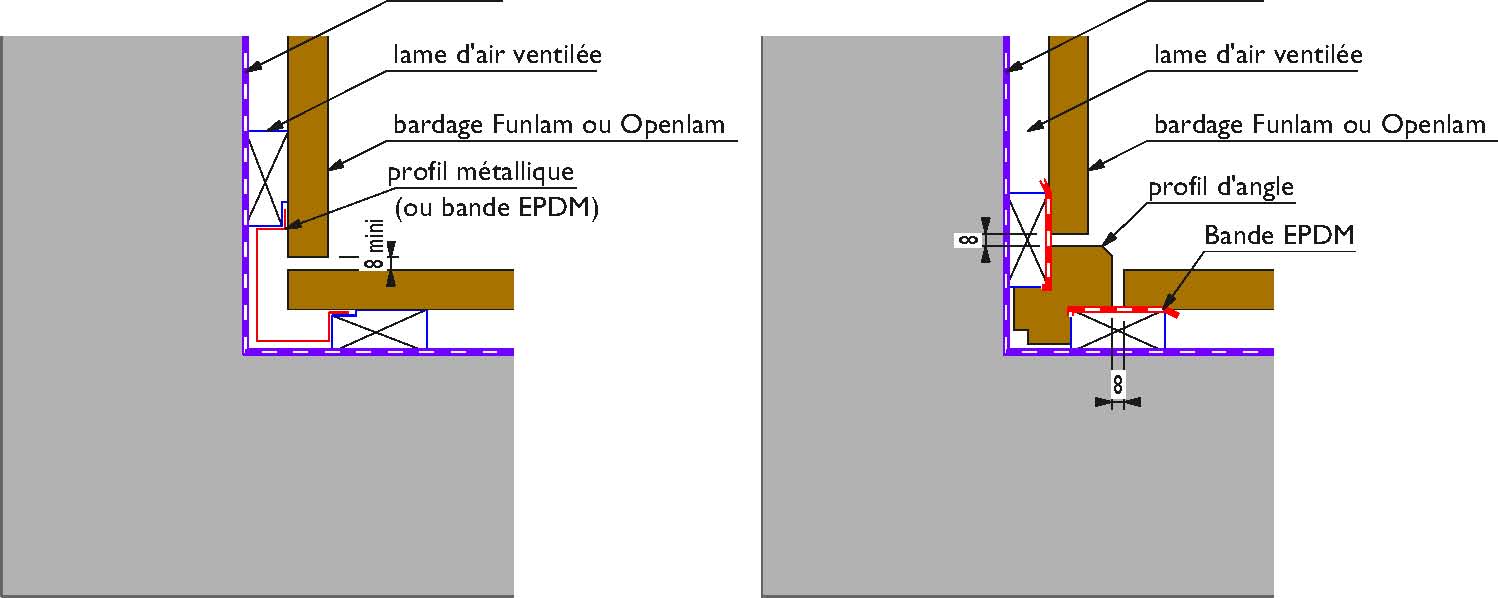

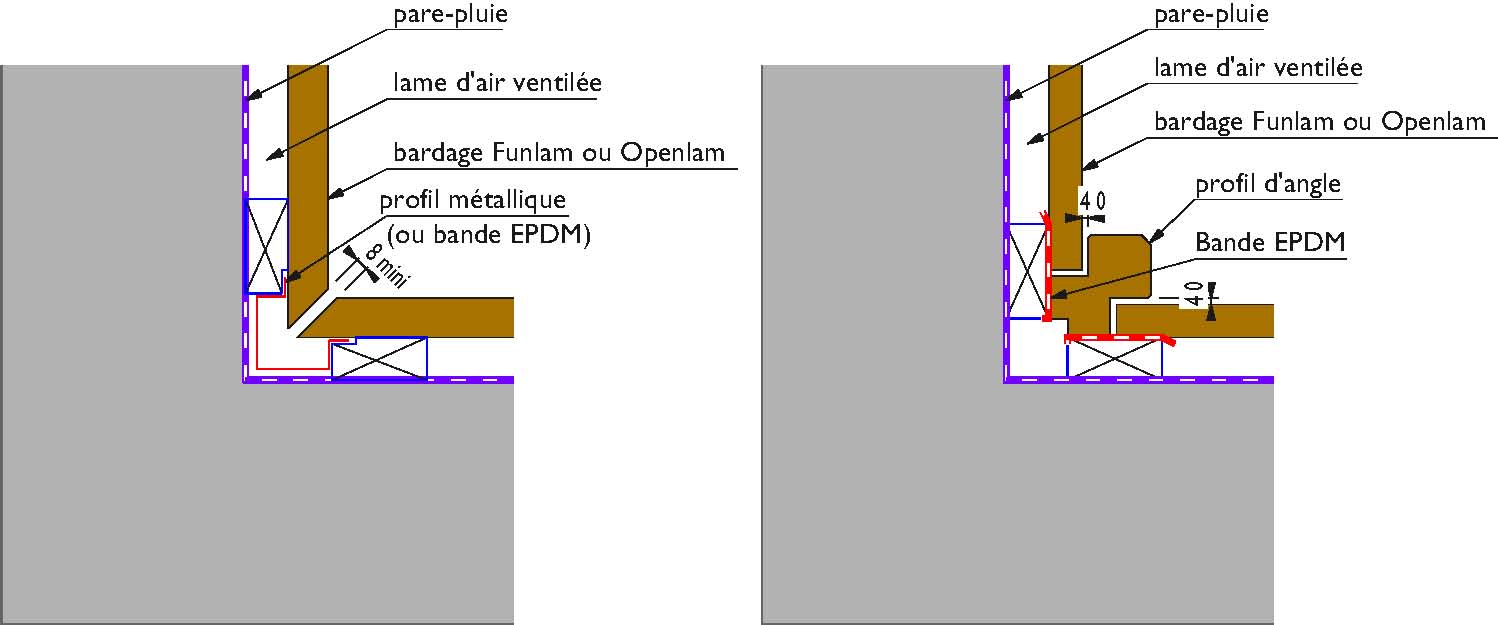

Details and advises/recommendations for installation

The Openlam® cladding combined with the exclusive casings for openings ensure the durability of the structure. An installation according to the national standards and the care given to each detail determine the quality of a cladding.

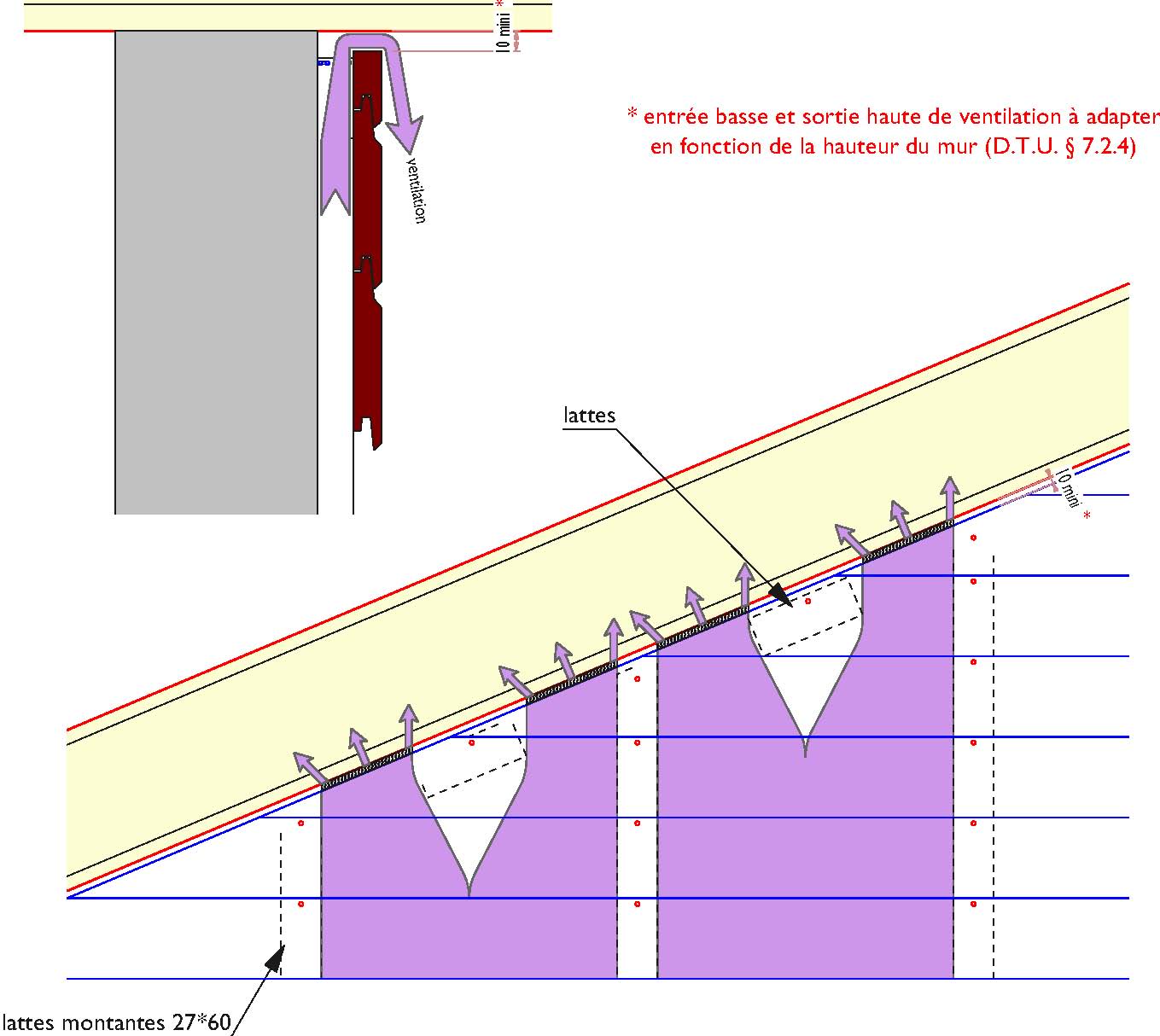

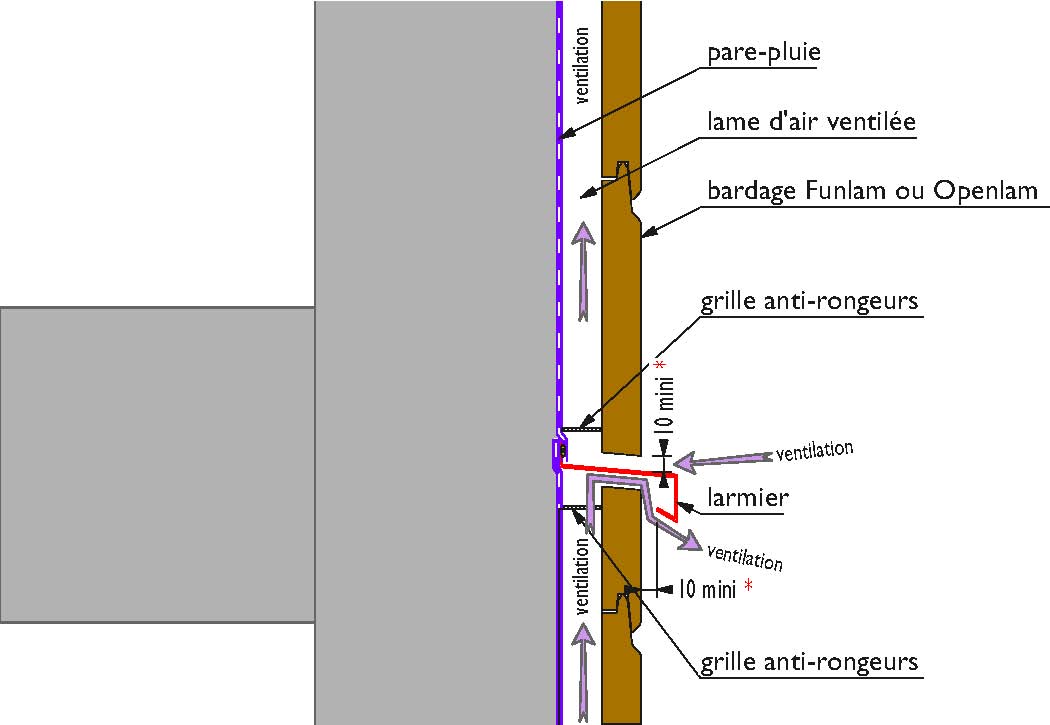

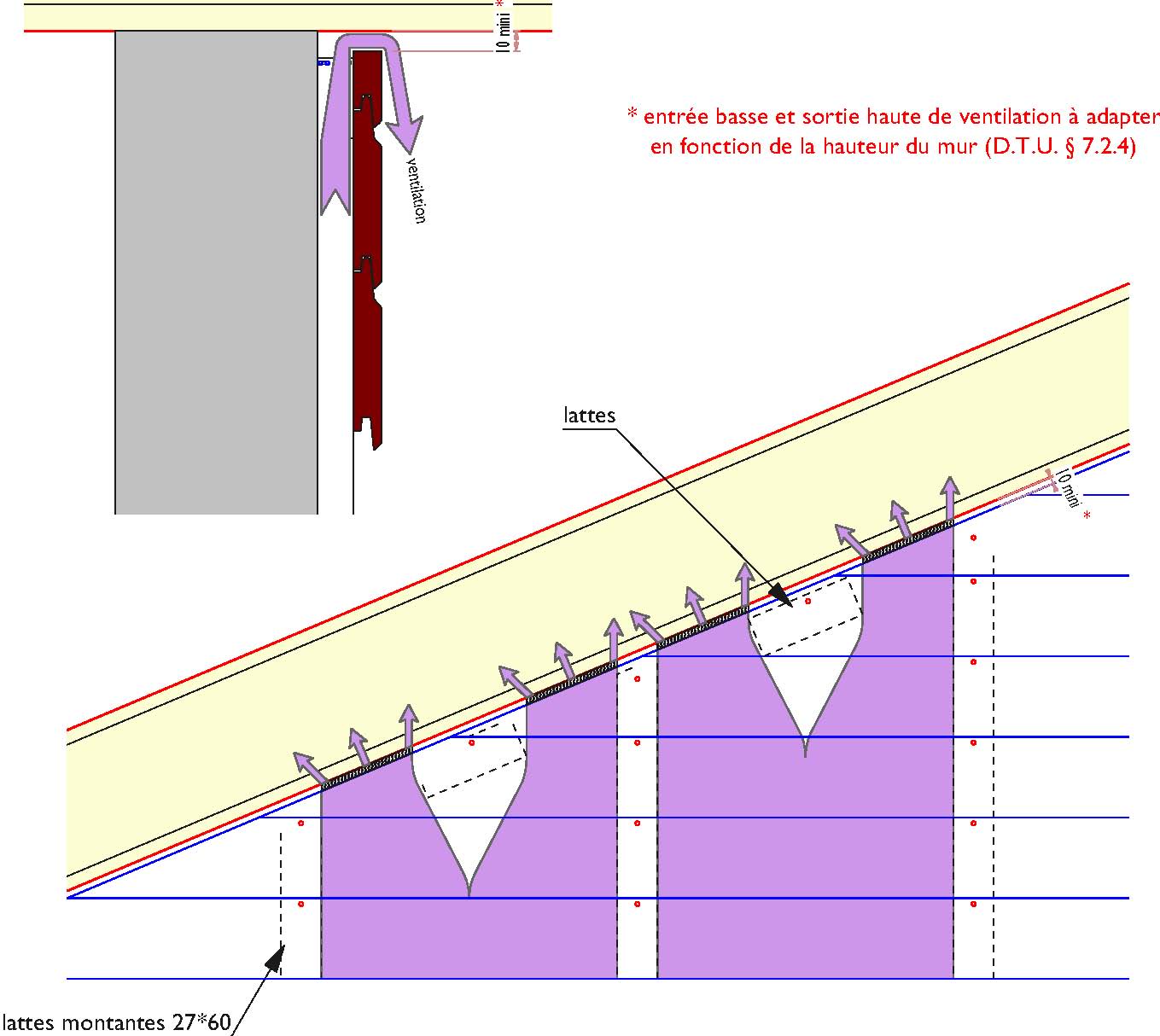

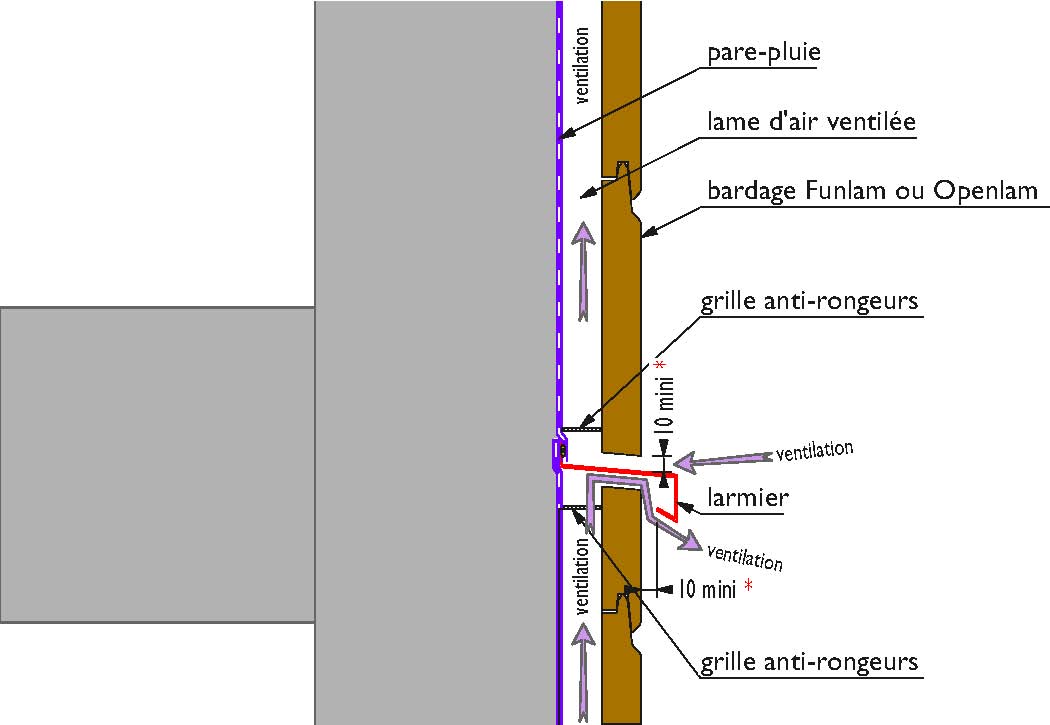

Ensure good ventilation

- Use battens of minimum 27 mm thickness (or more) to improve air circulation behind the cladding.

- The presence of the top and bottom ventilation.

The bottom and top of the walls must not be obstructed and must have an insect grid.

The constant upward air flow prevents the stagnation of heat and humidity on the back of the cladding (summer comfort).

To ensure the tightness

We recommend the installation of our casings on openings. Adaptable to all our sidings, they guarantee water-and air-tightness

It is important to treat and paint the ends of each profile (when cutting on site). We recommend the use of our incoming and outgoing angle profiles.

Avoid contact of the profile ends with another piece of timber, there must be kept an air gap in the joint.

Provide a suitable breather membrane

Wood fiber as thermal insulation from the outside ensures the role of breather membrane.

Respect the distance to the ground

In order to ensure the sustainability of the work, the siding must be at least 20 cm above the ground.

Prevent the development of vegetation near the cladding.

Horizontal leveling

Tracing on the supports every 120 or 190 mm keeps the entire periphery of the building aligned, each level of cladding board avoiding the dispersion of dimensions.

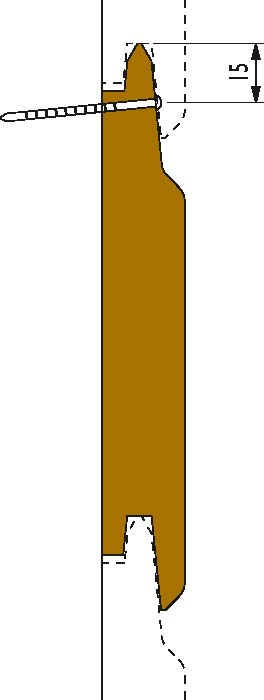

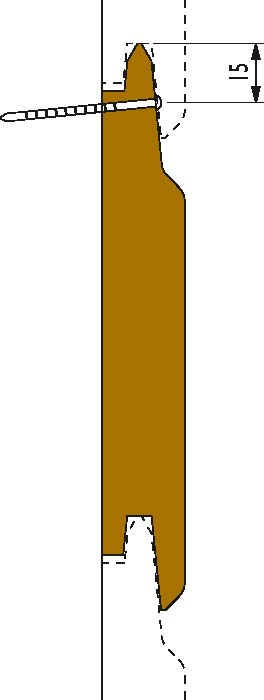

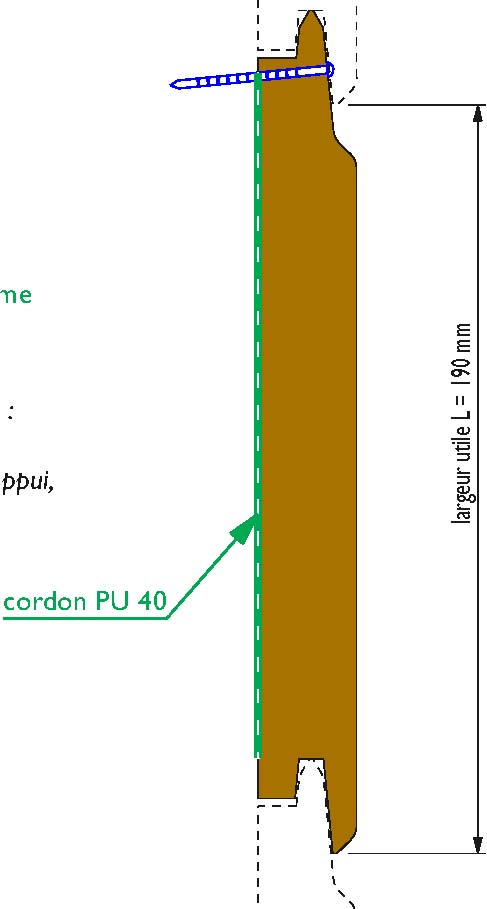

Fasten with stainless steel nails

The fastening must be done with stainless steel nails. The thickness of the battens should be adapted to the length of the nails and the penetration comply with regulations.

Technical characteristics of SIMONIN cladding

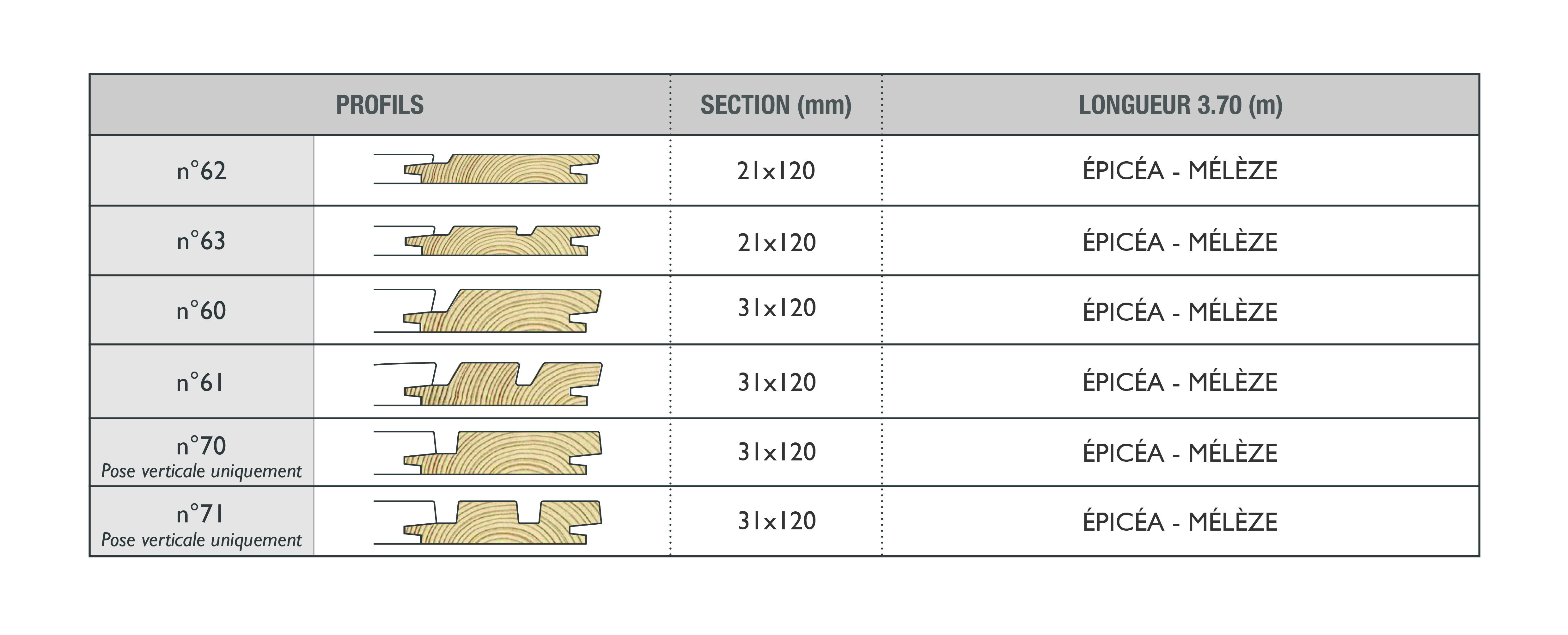

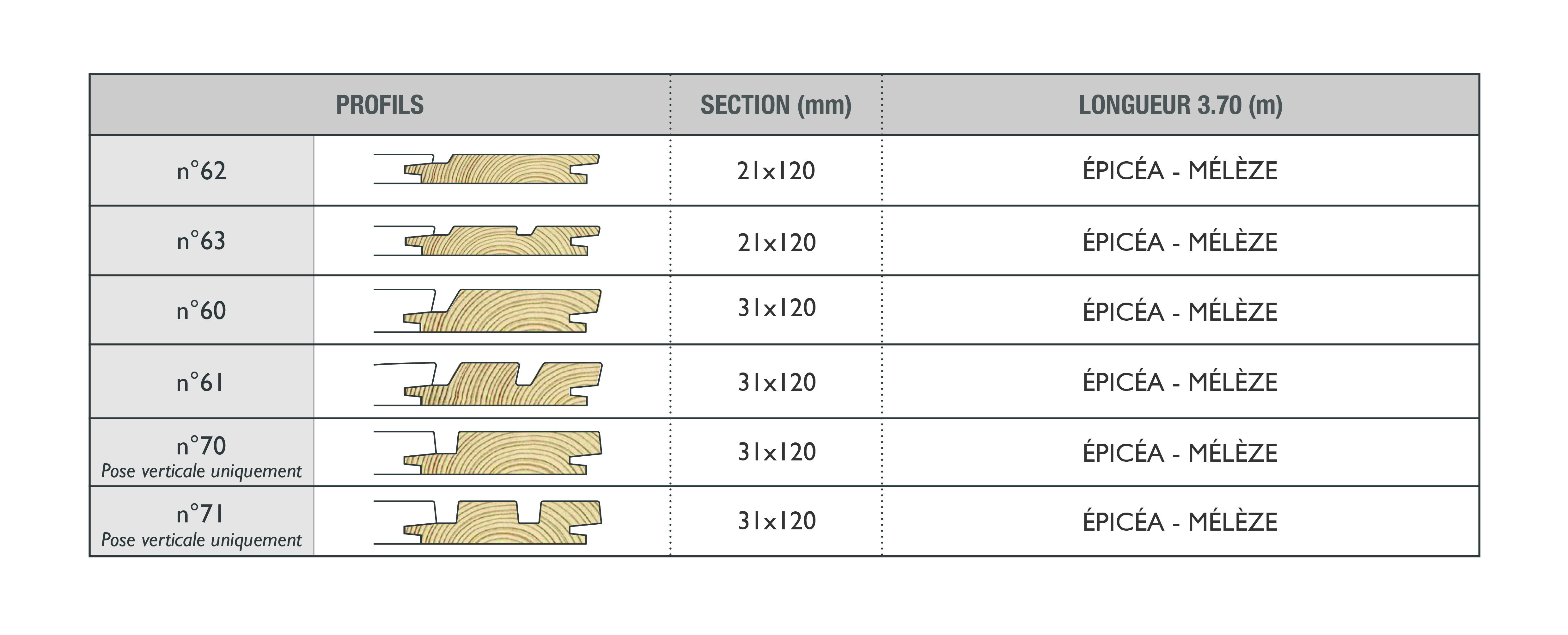

Openlam® product line

Openlam® profiles

Toutes les découpes éventuelles doivent être traitées avec un produit insecticide, fongicide et anti-termites avant application de la finition.

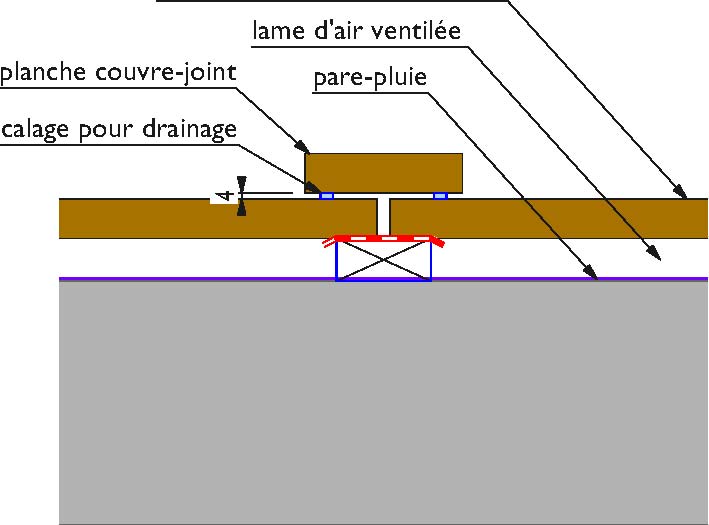

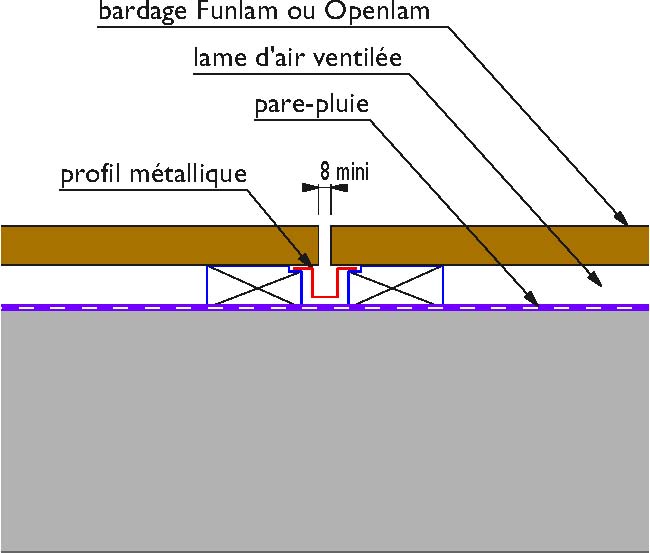

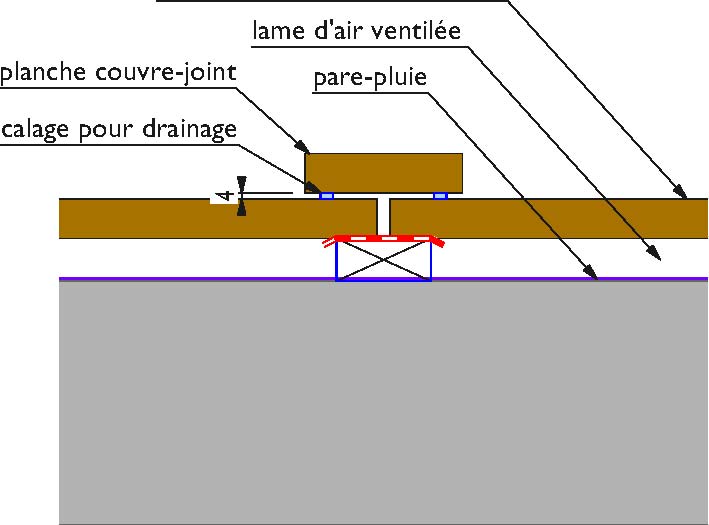

Détail de principe “drainant”

Nota : Le confort d’été peut être amélioré en augmentant l’épaisseur du lambourdage (ex : 40 mm) qui supporte le bardage et en augmentant la taille des entrées et sorties d’air, qui favorisent la bonne ventilation.

Attention : La ventilation ne doit en aucun cas être obstruée pendant et après la mise en oeuvre du bardage. (exemple : chute de gravats derrière le bardage, pare-pluie ou bande d’arase qui recouvre les grilles…)

Détail de principe “ventilation”

| Extrait DTU 41.2 : 7.2 Protection aux intempéries

7.2.4 Lames d’air

La lame d’air est ménagée par des tasseaux disposés verticalement ou par un double tasseautage. Elle est efficacement ventilée lorsque :

– Son épaisseur nominale est au moins égale à 20 mm

– Les entrées basses constituées par les trous de la grille anti-rongeurs et sorties de ventilation sont de section suffisante :

50 cm2 /ml de largeur de bardage pour une hauteur au plus égale à 3 m ;

65 cm2 /ml de largeur de bardage pour une hauteur de 3 m à 6 m ;

80 cm2 /ml de largeur de bardage pour une hauteur de 6 m à 10 m ;

100 cm2 /ml de largeur de bardage pour une hauteur de 10 m à 18 m ;

120 cm2 /ml de largeur de bardage pour une hauteur de 18 m à 24 m ;

au delà de 24 m un fractionnement de la lame d’air est nécessaire. |

Conseillé par SIMONIN SAS :

(calculé avec des grilles anti-rongeurs avec 1/3 de vide pour 2/3 de plein)

épaisseur latte 27 mm minimum – Entrée / sortie d’air : 10 mm

épaisseur latte 27 mm minimum – Entrée / sortie d’air : 10 mm

épaisseur latte 27 mm minimum – Entrée / sortie d’air : 10 mm

épaisseur latte 33 mm minimum – Entrée / sortie d’air : 10 mm

épaisseur latte 40 mm minimum – Entrée / sortie d’air : 15 mm

épaisseur latte 40 mm minimum – Entrée / sortie d’air : 15 mm |

Détail de principe “drainant” Simonin – Bardage – toiture

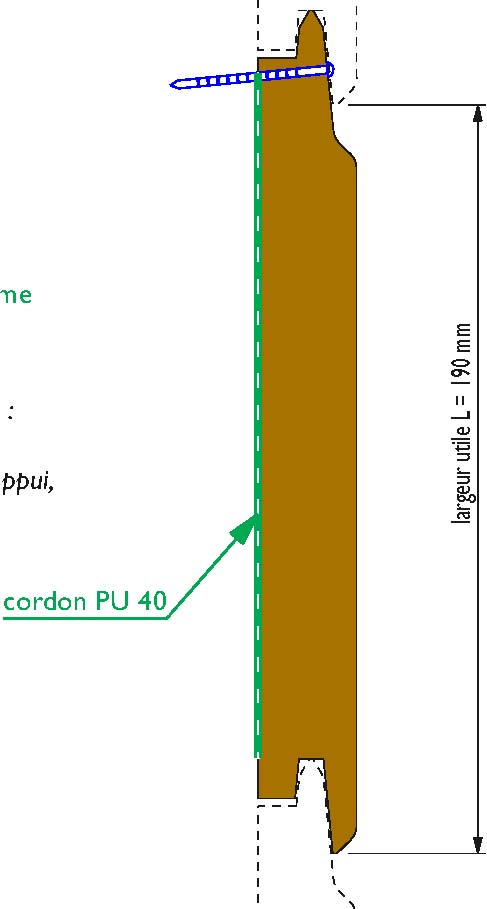

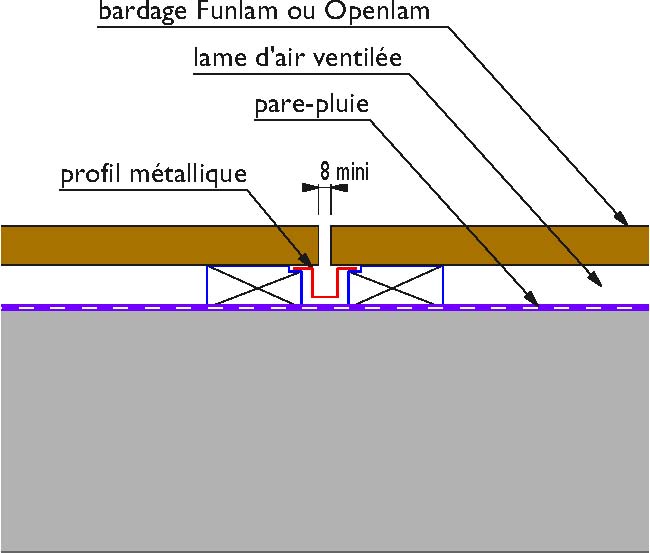

Détail de principe Simonin – Fixation de bardage avec et sans finition

largeur Funlam et Openlam = 120 mm : 1 fixation

largeur Funlam et Openlam = 120 mm : 1 fixation

Préconisation SIMONIN :

Préconisation SIMONIN :

fixation haute cachée

+ collage du bardage sur chaque lambourde avec cordon de colle mastic P.U. 40 de diamètre 6 mm minimum sur toute la largeur de la lame (consommation : environ 1 cartouche pour 10 m2 de bardage)

Nota : Cette préconisation a fait l’objet de différents essais au FCBA : Essais de résistance aux chocs et essais de stabilité sous sollicitation hygrothermique, avec dossier technique à l’appui, qui attestent du bon comportement des lames.

ou

Double fixation selon le DTU 41.2

Glulam

Glulam

Résix®

Résix®

Roof insulating panels

Roof insulating panels

Fire resistant timber slab

Fire resistant timber slab

Wall and floor

Wall and floor

Wall and floor

Wall and floor

Manuportable timber

Manuportable timber

Wood openwork cladding

Wood openwork cladding

Solid wood cladding

Solid wood cladding

Préconisation SIMONIN :

Préconisation SIMONIN :  Since 1967, Simonin has specialised in the design and manufacture of glued laminated timber structures and the manufacture of wooden components for construction. Our experience allows us constantly innovate and to develop new solutions for the most complex projects.

Since 1967, Simonin has specialised in the design and manufacture of glued laminated timber structures and the manufacture of wooden components for construction. Our experience allows us constantly innovate and to develop new solutions for the most complex projects.